Centrifugal Pump Analysis

Source:https://www.cedengineering.com/

Author(s):Shashi Menon, Ph.D., P.E.

Introduction

Centrifugal pumps are used to increase pressure in a liquid for the purpose of transporting the liquid through piping and other devices for use in an industrial process. With the higher pressure, the liquid can be transported in short or long pipelines for delivery to an ultimate destination. Examples include water pipelines, refined petroleum and crude oil pipelines.

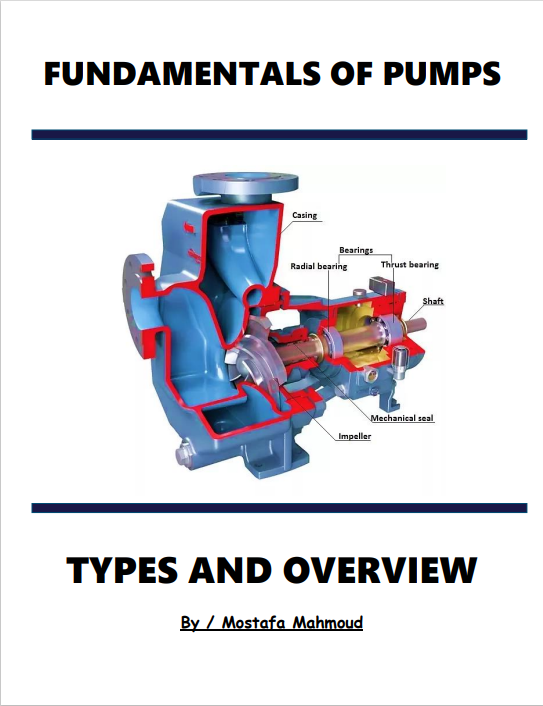

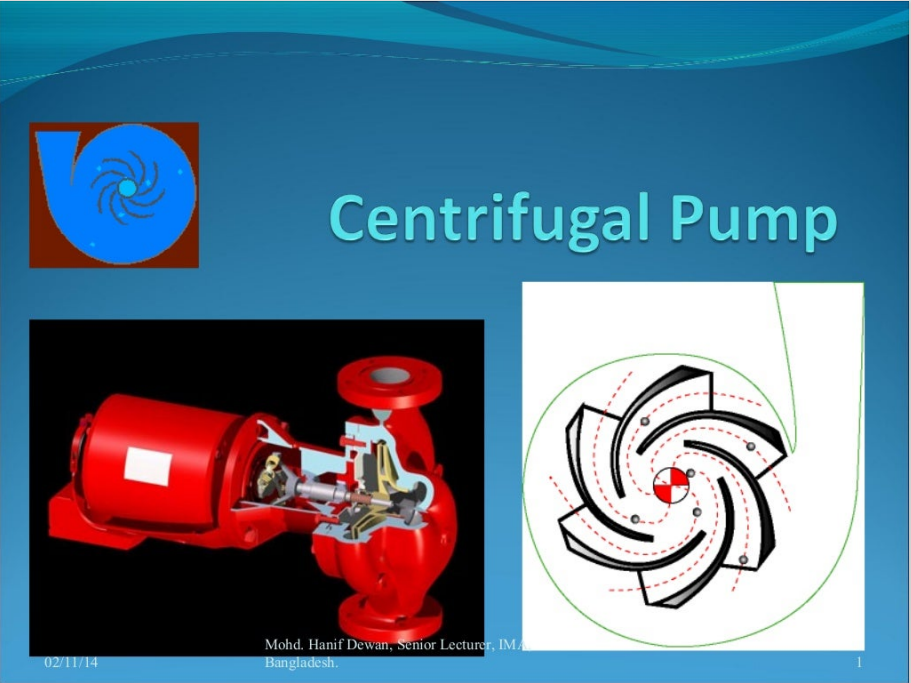

The pressure generated by the pump is gradually depleted as the liquid flows through the pipeline, due to friction in the pipe, as well as any elevation increase from the point of origin to the destination point. The liquid as it enters the pump has a certain amount of energy, due to its initial pressure (pressure energy), position (potential energy) and its velocity (kinetic energy). The potential energy depends on the location of the liquid from some datum, such as sea level. The kinetic energy is due to the motion of the liquid. The sum of three components is the total energy of the liquid. As the liquid comes out of the pump, energy is imparted by the rotating element (impeller) in the pump and the liquid pressure increases. The velocity of the liquid also changes from that at the pump inlet. In a centrifugal pump, the liquid is accelerated by centrifugal force during its passage through the rotating pump impeller and, finally at the exit, the kinetic energy is converted to pressure energy as it exits the pump volute into the discharge piping.

Only logged in customers who have purchased this product may leave a review.

Related products

Centrifugal Pump Application and Optimization

Centrifugal Pump Application and Optimization

Hydraulic Machines

- Pumps

- Turbine s

Hydraulic Machines

- Pumps

- Turbine s

Reviews

There are no reviews yet.