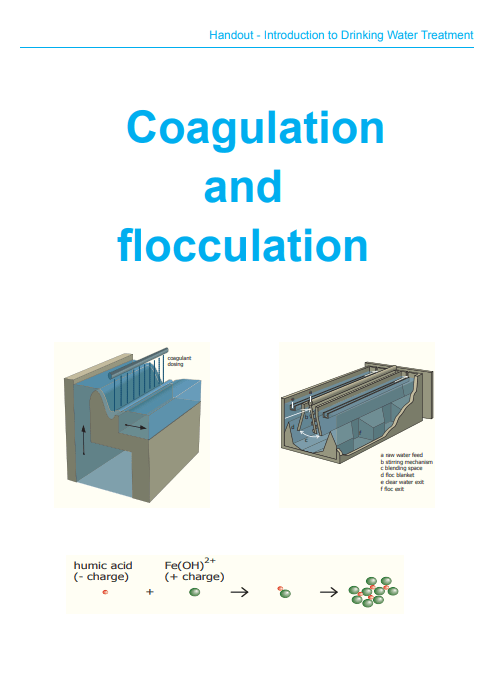

Coagulation and Flocculation

Source: https://ocw.tudelft.nl/

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Drinking Water Treatment

Only logged in customers who have purchased this product may leave a review.

Related products

Adsorbent Material Used In Water Treatment-A Review

Adsorption method of purify water relies mainly on the adsorbent to adsorb the impurities in the water, this paper introduces the latest research progress both at home and abroad, such as activated carbon, chitosan, zeolites, clay minerals plant-based, industrial waste . These adsorbent type will play a more and more important role in water treatment in the future.

Adsorbent Material Used In Water Treatment-A Review

Adsorption method of purify water relies mainly on the adsorbent to adsorb the impurities in the water, this paper introduces the latest research progress both at home and abroad, such as activated carbon, chitosan, zeolites, clay minerals plant-based, industrial waste . These adsorbent type will play a more and more important role in water treatment in the future.

Package Plants For Drinking Water Treatment

In efforts to make package plants more compact, affordable and easier to operate and maintain, it has been noted that the design and performance of some of these plants containing conventional treatment processes is sometimes compromised if technical expertise in this regard is lacking. Generally, there are several risks associated with poorly designed treatment systems, including loss of production, poor safety and compromised equipment and process unit efficiency with associated higher operating and maintenance costs. These risks have more severe consequences in the case of desalination (including water reclamation and water re-use) package plants. The objective of this project is to develop a set of guidelines to assist municipalities, water treatment practitioners, designers and package plant manufacturers in the specification and design of appropriate unit processes and operating parameters to fit the influent water quality, operating environment and other special treatment requirements.

Package Plants For Drinking Water Treatment

In efforts to make package plants more compact, affordable and easier to operate and maintain, it has been noted that the design and performance of some of these plants containing conventional treatment processes is sometimes compromised if technical expertise in this regard is lacking. Generally, there are several risks associated with poorly designed treatment systems, including loss of production, poor safety and compromised equipment and process unit efficiency with associated higher operating and maintenance costs. These risks have more severe consequences in the case of desalination (including water reclamation and water re-use) package plants. The objective of this project is to develop a set of guidelines to assist municipalities, water treatment practitioners, designers and package plant manufacturers in the specification and design of appropriate unit processes and operating parameters to fit the influent water quality, operating environment and other special treatment requirements.

Biofilm Control Study

Darigold operates a milk products facility in Lynden, Washington. Production processes include evaporation of milk, which generates what is referred to as condensate of whey (COW) water. COW water contains low molecular weight organic compounds including traces of lactic acid, alcohols, acetoin, and non-protein nitrogen (Möslang, 2017). COW water and non-contact cooling water from the Darigold Lynden facility are currently discharged to Outfall 001, which combines with stormwater and the City of Lynden’s wastewater treatment plant (WWTP) effluent discharge to the Nooksack River through the City’s outfall. Darigold’s discharge is regulated under National Pollutant Discharge Elimination System (NPDES) Permit No. WA0002470 administered by the Washington Department of Ecology (Ecology). In the future, Darigold’s COW Water and non-contact cooling water will be directly discharged to the Nooksack River in a new outfall pipe (Outfall 002) currently being constructed by the City.

Biofilm Control Study

Darigold operates a milk products facility in Lynden, Washington. Production processes include evaporation of milk, which generates what is referred to as condensate of whey (COW) water. COW water contains low molecular weight organic compounds including traces of lactic acid, alcohols, acetoin, and non-protein nitrogen (Möslang, 2017). COW water and non-contact cooling water from the Darigold Lynden facility are currently discharged to Outfall 001, which combines with stormwater and the City of Lynden’s wastewater treatment plant (WWTP) effluent discharge to the Nooksack River through the City’s outfall. Darigold’s discharge is regulated under National Pollutant Discharge Elimination System (NPDES) Permit No. WA0002470 administered by the Washington Department of Ecology (Ecology). In the future, Darigold’s COW Water and non-contact cooling water will be directly discharged to the Nooksack River in a new outfall pipe (Outfall 002) currently being constructed by the City.

Best Practices Manual for Small Drinking Water Systems

New regulations pursuant to The Drinking Water Safety Act, administered by the Office of Drinking Water, resulted in changes to the approval, licensing, monitoring, record-keeping and reporting requirements for drinking water systems in Manitoba. It is recognized that many small drinking water systems may not have the same level of access to technical services and resources as larger public water systems. This manual of best practices (a comprehensive, integrated and co-operative approach to continuous improvement of all facets of operations for delivering superior standards of performance) is to assist small drinking water systems with regulatory, management and operational challenges.

Best Practices Manual for Small Drinking Water Systems

New regulations pursuant to The Drinking Water Safety Act, administered by the Office of Drinking Water, resulted in changes to the approval, licensing, monitoring, record-keeping and reporting requirements for drinking water systems in Manitoba. It is recognized that many small drinking water systems may not have the same level of access to technical services and resources as larger public water systems. This manual of best practices (a comprehensive, integrated and co-operative approach to continuous improvement of all facets of operations for delivering superior standards of performance) is to assist small drinking water systems with regulatory, management and operational challenges.

Module 11: Administration of Water Treatment Plants

• Describe how water treatment plants comply with their minimum federal and state monitoring requirements.

• List the three ways in which management ensures that the staff complies with monitoring requirements.

• Discuss reporting requirements when complying with federal and state regulations.

Module 11: Administration of Water Treatment Plants

• Describe how water treatment plants comply with their minimum federal and state monitoring requirements.

• List the three ways in which management ensures that the staff complies with monitoring requirements.

• Discuss reporting requirements when complying with federal and state regulations.

Removal of Aluminium from Drinking Water

Aluminium in drinking water comes from natural sources and the alum used as coagulant in the water treatment process. Exposure to aluminium has been implicated in dialysis dementia, Parkinson and Alzheimer’s disease. Drinking water containing aluminium was considered to be one of the main sources of Al intake into human body. For this reason, the removal of aluminium from drinking water is vital to our health. In this study, removal of aluminium was carried out by using a chelating resin.

Removal of Aluminium from Drinking Water

Aluminium in drinking water comes from natural sources and the alum used as coagulant in the water treatment process. Exposure to aluminium has been implicated in dialysis dementia, Parkinson and Alzheimer’s disease. Drinking water containing aluminium was considered to be one of the main sources of Al intake into human body. For this reason, the removal of aluminium from drinking water is vital to our health. In this study, removal of aluminium was carried out by using a chelating resin.

Activated Carbon Treatment of Drinking Water

Introduction:

Activated carbon filtration (AC) is effective in reducing certain organic chemicals and chlorine in water. It can also reduce the quantity of lead in water although most lead-reducing systems use another filter medium in addition to carbon. Water is passed through granular or block carbon material to reduce toxic compounds as well as harmless taste- and odor-producing chemicals. This fact sheet discusses the principles and processes of typical activated carbon filtration systems.

Activated Carbon Treatment of Drinking Water

Introduction:

Activated carbon filtration (AC) is effective in reducing certain organic chemicals and chlorine in water. It can also reduce the quantity of lead in water although most lead-reducing systems use another filter medium in addition to carbon. Water is passed through granular or block carbon material to reduce toxic compounds as well as harmless taste- and odor-producing chemicals. This fact sheet discusses the principles and processes of typical activated carbon filtration systems.

Reviews

There are no reviews yet.