Separation Theory, Membrane Operations, Preparation of Membranes

Separation Theory, Membrane Operations, Preparation of Membranes

Source: https://www.utm.my

Prepared By: Prof. Ir. Dr. Zaini ujang

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Water Desalination & RO

Only logged in customers who have purchased this product may leave a review.

Related products

Desalination & Water Purification Technologies

Introduction:

The world’s water consumption rate is doubling every 20 years, outpacing by two times the rate of population growth. The availability of good quality water is on the decline and water demand is on the rise. Worldwide availability of fresh water for industrial needs and human consumption is limited.

Various industrial and developmental activities in recent times have resulted in increasing the pollution level and deteriorating the water quality. Water shortages and unreliable water quality are considered major obstacles to achieve sustainable development and improvement in the quality of life. The water

demand in the country is increasing fast due to progressive increase in the demand of water for irrigation, rapid industrialization, and population growth and improving life standards. The existing water resources are diminishing (i) due to unequal distribution of rain water and occasional drought, (ii) excessive exploitation of ground water sources and its insufficient recharge, (iii) deterioration of water quality due to the discharge of domestic and industrial effluents without adequate treatment. This is resulting into water stress/ scarcity. Country is currently passing through social and economic transition.

The proportion of the population which is urban has doubled over the last thirty years (and is now about 30%), agriculture now accounts for about 25% of GDP and the economy has been growing at around 7-9% a year. Country has a highly seasonal pattern of rainfall, with 50% of precipitation falling

in just 15 days and over 90% of river flows in just four months

Desalination & Water Purification Technologies

Introduction:

The world’s water consumption rate is doubling every 20 years, outpacing by two times the rate of population growth. The availability of good quality water is on the decline and water demand is on the rise. Worldwide availability of fresh water for industrial needs and human consumption is limited.

Various industrial and developmental activities in recent times have resulted in increasing the pollution level and deteriorating the water quality. Water shortages and unreliable water quality are considered major obstacles to achieve sustainable development and improvement in the quality of life. The water

demand in the country is increasing fast due to progressive increase in the demand of water for irrigation, rapid industrialization, and population growth and improving life standards. The existing water resources are diminishing (i) due to unequal distribution of rain water and occasional drought, (ii) excessive exploitation of ground water sources and its insufficient recharge, (iii) deterioration of water quality due to the discharge of domestic and industrial effluents without adequate treatment. This is resulting into water stress/ scarcity. Country is currently passing through social and economic transition.

The proportion of the population which is urban has doubled over the last thirty years (and is now about 30%), agriculture now accounts for about 25% of GDP and the economy has been growing at around 7-9% a year. Country has a highly seasonal pattern of rainfall, with 50% of precipitation falling

in just 15 days and over 90% of river flows in just four months

Desalination Technology Trends And CH2M HILL

Presentation Outline:

- The Growing Desalination Market

- Trends in the Technology/Virtual expo

- Thermal Desalination

Desalination Technology Trends And CH2M HILL

Presentation Outline:

- The Growing Desalination Market

- Trends in the Technology/Virtual expo

- Thermal Desalination

Cleaning Your RO

Eventually the day comes when your RO system will require cleaning. Cleaning is recommended when your RO shows evidence of fouling, just prior to a long term shutdown, or as a matter of scheduled routine maintenance. Fouling characteristics that signal you need to clean are a 10-15% decrease in normalized permeate flow, a 10-15% decrease in normalized permeate quality, or a 10-15% increase in normalized pressure drop as measured between the feed and concentrate headers

Cleaning Your RO

Eventually the day comes when your RO system will require cleaning. Cleaning is recommended when your RO shows evidence of fouling, just prior to a long term shutdown, or as a matter of scheduled routine maintenance. Fouling characteristics that signal you need to clean are a 10-15% decrease in normalized permeate flow, a 10-15% decrease in normalized permeate quality, or a 10-15% increase in normalized pressure drop as measured between the feed and concentrate headers

Desalination: A National Perspective

NOTICE:

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The members of the panel responsible for the report were chosen for their special competences and with regard for appropriate balance.

Support for this study was provided by the U.S. Bureau of Reclamation under Grant No. 06CS811198. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the organizations or agencies that provided

support for the project.

Desalination: A National Perspective

NOTICE:

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The members of the panel responsible for the report were chosen for their special competences and with regard for appropriate balance.

Support for this study was provided by the U.S. Bureau of Reclamation under Grant No. 06CS811198. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the organizations or agencies that provided

support for the project.

Advanced Reverse Osmosis System Design

Overview of Advanced RO Design

• RO system design guideline variables

• Drivers for RO system configuration selection

• Principles and benefits of RO array flux balancing

• Array selection criteria to achieve permeate quality target

• Energy recovery

Advanced Reverse Osmosis System Design

Overview of Advanced RO Design

• RO system design guideline variables

• Drivers for RO system configuration selection

• Principles and benefits of RO array flux balancing

• Array selection criteria to achieve permeate quality target

• Energy recovery

Desalination and Water Treatment

Abstract:

This study proposes a simple design method of the Reverse osmosis (RO) system in RO brackish water desalination plants. This method is based on the application of maximum available recovery without scaling of any of the compounds present in the water as silica, calcium carbonate, calcium sulfate, barium sulfate, strontium sulfate, and calcium fluoride, and membrane manufacturer design guidelines, and the plant production. Although the method was originally

conceived for application to subterranean brackish waters in the Canary Islands, Spain (principally Gran Canaria, Fuerteventura and Tenerife), it can be extrapolated to other types of region and water treatable with RO systems. The required input data are the chemical composition of the feed water, pH, temperature, silt density index membrane manufacturer design guidelines, and the plant production. The programmed method then determines the design of the RO system. The method whose procedure is described graphically and analytically can be used as an aid in design optimization of RO brackish water desalination plants with acid-free pretreatment processes and only the use of scale inhibitor using spiral wound membranes. Practical applications are presented. The final results for different types of feed water and capacities are showed.

Desalination and Water Treatment

Abstract:

This study proposes a simple design method of the Reverse osmosis (RO) system in RO brackish water desalination plants. This method is based on the application of maximum available recovery without scaling of any of the compounds present in the water as silica, calcium carbonate, calcium sulfate, barium sulfate, strontium sulfate, and calcium fluoride, and membrane manufacturer design guidelines, and the plant production. Although the method was originally

conceived for application to subterranean brackish waters in the Canary Islands, Spain (principally Gran Canaria, Fuerteventura and Tenerife), it can be extrapolated to other types of region and water treatable with RO systems. The required input data are the chemical composition of the feed water, pH, temperature, silt density index membrane manufacturer design guidelines, and the plant production. The programmed method then determines the design of the RO system. The method whose procedure is described graphically and analytically can be used as an aid in design optimization of RO brackish water desalination plants with acid-free pretreatment processes and only the use of scale inhibitor using spiral wound membranes. Practical applications are presented. The final results for different types of feed water and capacities are showed.

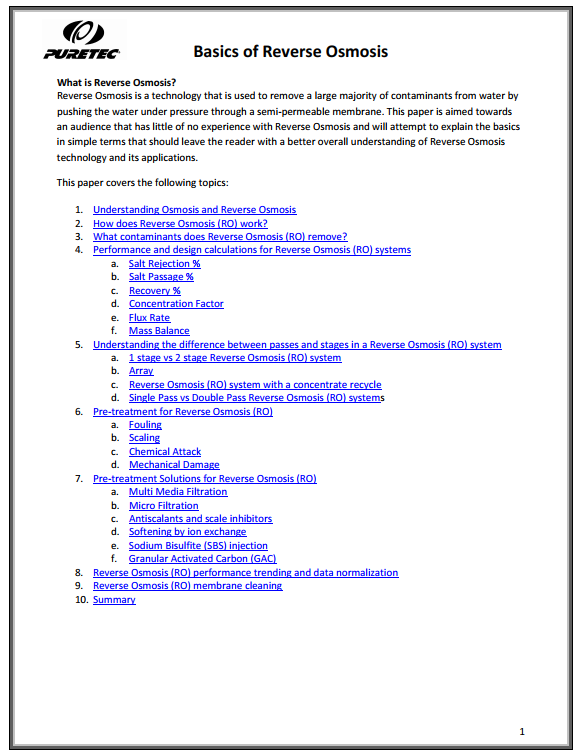

Basics of Reverse Osmosis

What is Reverse Osmosis?

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by

pushing the water under pressure through a semi permeable membrane. This paper is aimed towards an audience that has little of no experience with Reverse Osmosis and will attempt to explain the basics

in simple terms that should leave the reader with a better overall understanding of Reverse Osmosis technology and its applications.

Basics of Reverse Osmosis

What is Reverse Osmosis?

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by

pushing the water under pressure through a semi permeable membrane. This paper is aimed towards an audience that has little of no experience with Reverse Osmosis and will attempt to explain the basics

in simple terms that should leave the reader with a better overall understanding of Reverse Osmosis technology and its applications.

California Desalination Planning Handbook

Introduction:

Desalination is receiving increased attention as a means for addressing the water supply challenges of California. Growing population, much of which is located in semi-arid regions of the state, and various other water demands pose increased pressure on existing water supplies. Much of California’s water supply depends on snow accumulation in the winter, providing spring runoff that flls reservoirs and replenishes often depleted groundwater supplies. But in periods of drought, water supply shortages can be encountered throughout the state, particularly in the central valley and southern portion of the state. All indications suggest the impacts of global warming will include a change in the timing of runoff and less snowfall. This will put more pressure on existing supplies, and exacerbate the impacts of drought. As the implications of global warming become clearer, more emphasis will likely be given to developing

new sources of water supply to meet existing and projected demand. While conservation and recycling are recommended as the frst course of action, other alternatives (such as desalination and increased surface and groundwater storage) are receiving increased attention.

California Desalination Planning Handbook

Introduction:

Desalination is receiving increased attention as a means for addressing the water supply challenges of California. Growing population, much of which is located in semi-arid regions of the state, and various other water demands pose increased pressure on existing water supplies. Much of California’s water supply depends on snow accumulation in the winter, providing spring runoff that flls reservoirs and replenishes often depleted groundwater supplies. But in periods of drought, water supply shortages can be encountered throughout the state, particularly in the central valley and southern portion of the state. All indications suggest the impacts of global warming will include a change in the timing of runoff and less snowfall. This will put more pressure on existing supplies, and exacerbate the impacts of drought. As the implications of global warming become clearer, more emphasis will likely be given to developing

new sources of water supply to meet existing and projected demand. While conservation and recycling are recommended as the frst course of action, other alternatives (such as desalination and increased surface and groundwater storage) are receiving increased attention.

Desalination and Membrane Technologies: Federal Research and Adoption Issues

In the United States, desalination and membrane technologies are used to augment municipal water supply, produce high-quality industrial water supplies, and reclaim contaminated supplies (including from oil and gas development). Approximately 2,000 desalination facilities larger than

0.3 million gallons per day (MGD) operate in the United States; this represents more than 2% of U.S. municipal and industrial freshwater use. At issue for Congress is what should be the federal role in supporting desalination and membrane technology research and facilities. Desalination issues before the 114th Congress may include how to focus federal research, at what level to support desalination research and projects, and how to provide a regulatory context that protects the environment and public health without disadvantaging desalination’s adoption.

Desalination and Membrane Technologies: Federal Research and Adoption Issues

In the United States, desalination and membrane technologies are used to augment municipal water supply, produce high-quality industrial water supplies, and reclaim contaminated supplies (including from oil and gas development). Approximately 2,000 desalination facilities larger than

0.3 million gallons per day (MGD) operate in the United States; this represents more than 2% of U.S. municipal and industrial freshwater use. At issue for Congress is what should be the federal role in supporting desalination and membrane technology research and facilities. Desalination issues before the 114th Congress may include how to focus federal research, at what level to support desalination research and projects, and how to provide a regulatory context that protects the environment and public health without disadvantaging desalination’s adoption.

Desalination Plant Basis Of Design

Overview:

The project potable water requirements will be provided using single desalination plant with the Grand Bahama Port Authority water supply serving as the backup source. The overall desalination treatment process will consist of feedwater pumping, bag filtration, optional media filtration, the addition of a scale

inhibitor, cartridge filtration, membrane separation, forced air degasification, re-pumping, and post treatment. Provisions have been included to bypass the post treatment systems for the production of irrigation water. The post aeration re-pump station will be designed to transfer either type of water to the

appropriate storage tanks located within the project. Membrane concentrate will be disposed via an injection well to be constructed as part of this project.

The desalination process will consist of a dual treatment units or “trains” each equipped with a positive displacement axial piston first pass membrane feed pump, first pass membrane array, energy recovery system, second pass membrane feed pump, second pass membrane array, high- and low-pressure

piping and instrumentation. The second pass system is designed to treat up to 60 percent of the first pass permeate. A membrane cleaning/flush system will be provided. The membrane post treatment will be designed to receive the flow from both units and consists of a forced air degasified, repumping, recarbonation, calcium carbonate up flow contactors to boost finished water hardness and alkalinity concentrations; and three chemical feed systems for the metering of a corrosion inhibitor, dilute hydrochloric acid for pH adjustment and sodium hypochlorite for residual disinfection. The final pH and chlorine residual will be controlled and recorded by a separate system. The following sections describe the various aspects of the facility in greater detail. Process flow

schematics are presented in Appendix A.

Desalination Plant Basis Of Design

Overview:

The project potable water requirements will be provided using single desalination plant with the Grand Bahama Port Authority water supply serving as the backup source. The overall desalination treatment process will consist of feedwater pumping, bag filtration, optional media filtration, the addition of a scale

inhibitor, cartridge filtration, membrane separation, forced air degasification, re-pumping, and post treatment. Provisions have been included to bypass the post treatment systems for the production of irrigation water. The post aeration re-pump station will be designed to transfer either type of water to the

appropriate storage tanks located within the project. Membrane concentrate will be disposed via an injection well to be constructed as part of this project.

The desalination process will consist of a dual treatment units or “trains” each equipped with a positive displacement axial piston first pass membrane feed pump, first pass membrane array, energy recovery system, second pass membrane feed pump, second pass membrane array, high- and low-pressure

piping and instrumentation. The second pass system is designed to treat up to 60 percent of the first pass permeate. A membrane cleaning/flush system will be provided. The membrane post treatment will be designed to receive the flow from both units and consists of a forced air degasified, repumping, recarbonation, calcium carbonate up flow contactors to boost finished water hardness and alkalinity concentrations; and three chemical feed systems for the metering of a corrosion inhibitor, dilute hydrochloric acid for pH adjustment and sodium hypochlorite for residual disinfection. The final pH and chlorine residual will be controlled and recorded by a separate system. The following sections describe the various aspects of the facility in greater detail. Process flow

schematics are presented in Appendix A.

Reviews

There are no reviews yet.