Introduction to Piping Design

• As per Merriam Webster dictionary , the pipe is a long tube or hollow body for conducting a liquid, gas, or finely divided solid.

• Technically : The pipe Is a beam , which acts as pressure vessel and transfer fluids.

Introduction to Piping Design

• As per Merriam Webster dictionary , the pipe is a long tube or hollow body for conducting a liquid, gas, or finely divided solid.

• Technically : The pipe Is a beam , which acts as pressure vessel and transfer fluids.

Inspect New Piping

Piping systems are like arteries and veins in the oil industry. Piping systems comprise of pipes, flanges, bolting, gaskets, valves etc. They also include pipe hangers, supporting elements and other items necessary to prevent over pressurization and over stressing of the pressure containing components. Hence, one can say that pipe section when fitted with valves and other mechanical equipment and properly supported by hangers and supports are called piping.

Inspect New Piping

Piping systems are like arteries and veins in the oil industry. Piping systems comprise of pipes, flanges, bolting, gaskets, valves etc. They also include pipe hangers, supporting elements and other items necessary to prevent over pressurization and over stressing of the pressure containing components. Hence, one can say that pipe section when fitted with valves and other mechanical equipment and properly supported by hangers and supports are called piping.

Hydraulic Study For The New Cairo Raw Water Pipeline

phase is expected to be completed by the end of 2011. The system consists of one raw water intake pump station (IPS), three booster pump stations (BPS 2, 3, and 4), and multiple parallel 2200-millimeter (mm) and 2600-mm diameter pipelines that run approximately 30 kilometers (km) from the Nile River to the newly constructed New Cairo Potable Water Treatment Plant (WTP). Construction will be completed in eight pump installation phases, with design flows ranging from 6 cubic meters per second (m3/sec) at Phase 1 to an ultimate flow of 48 m3 Because the pumping capacity required for Phases 5-8 is to be supplied by a parallel system of pump stations and pipelines that mirror Phases 1-4 (with identical hydraulics and capacities), the following report is based on analysis of Phases 1-4 only. The ultimate flow rate for Phase 4 is 24 m /sec at Phase 8.

Hydraulic Study For The New Cairo Raw Water Pipeline

phase is expected to be completed by the end of 2011. The system consists of one raw water intake pump station (IPS), three booster pump stations (BPS 2, 3, and 4), and multiple parallel 2200-millimeter (mm) and 2600-mm diameter pipelines that run approximately 30 kilometers (km) from the Nile River to the newly constructed New Cairo Potable Water Treatment Plant (WTP). Construction will be completed in eight pump installation phases, with design flows ranging from 6 cubic meters per second (m3/sec) at Phase 1 to an ultimate flow of 48 m3 Because the pumping capacity required for Phases 5-8 is to be supplied by a parallel system of pump stations and pipelines that mirror Phases 1-4 (with identical hydraulics and capacities), the following report is based on analysis of Phases 1-4 only. The ultimate flow rate for Phase 4 is 24 m /sec at Phase 8.

Presentation on Fundamentals of Pipeline Design

➢The amount of fluid flow through the pipeline is one of the first items of information required for design

➢ Different industries use pipeline for different purposes. requirements & types of pipe are different

➢ Petroleum industry & natural gas industry use steel pipe with welded joints.

➢ This allows the pipeline to withstand very high pressure, sometimes above 3000 psig

➢ High pressure allow the use of long pipelines, often more then 1000 miles with only a booster pump or station for each pipeline

➢ Some pipelines are designed with some excess capacity or design so capacity can be increased by the addition of compression or pumping horsepower

Presentation on Fundamentals of Pipeline Design

➢The amount of fluid flow through the pipeline is one of the first items of information required for design

➢ Different industries use pipeline for different purposes. requirements & types of pipe are different

➢ Petroleum industry & natural gas industry use steel pipe with welded joints.

➢ This allows the pipeline to withstand very high pressure, sometimes above 3000 psig

➢ High pressure allow the use of long pipelines, often more then 1000 miles with only a booster pump or station for each pipeline

➢ Some pipelines are designed with some excess capacity or design so capacity can be increased by the addition of compression or pumping horsepower

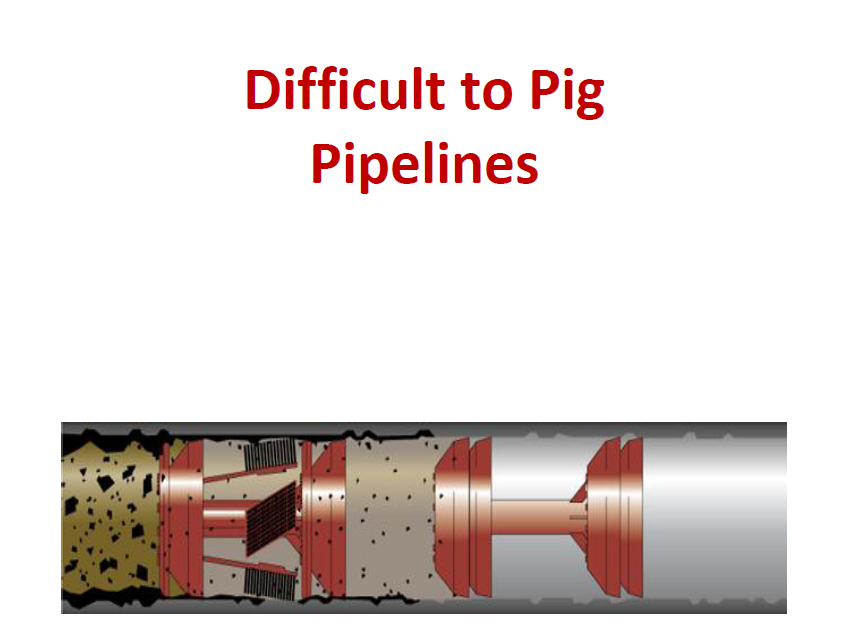

Difficult to Pig Pipelines

Pigging : A widely utilized process which is the act of propelling a properly sized spherical or cylindrical device through the interior of a pipeline by manipulating the pressure & flow of the existing media, or by artificially introduced media or by mechanically pulling the device through the pipeline for the

specific purpose of cleaning, inspecting or distributing inhibitor throughout the pipeline.

Difficult to Pig Pipelines

Pigging : A widely utilized process which is the act of propelling a properly sized spherical or cylindrical device through the interior of a pipeline by manipulating the pressure & flow of the existing media, or by artificially introduced media or by mechanically pulling the device through the pipeline for the

specific purpose of cleaning, inspecting or distributing inhibitor throughout the pipeline.

Flow Measurement in Pipes and Ducts

This course is about measurement of the flow rate of a fluid flowing under pressure in a closed conduit. The closed conduit is often circular, but also may be square or rectangular (such as a heating duct) or any other shape. The other major category of flow is open channel flow, which is the flow of a liquid with a free surface open to atmospheric pressure. Measurement of the flow rate of a fluid flowing under pressure, is carried out for a variety of purposes, such as billing for water supply to homes or businesses or, for monitoring or process control of a wide variety of industrial processes that involve flowing fluids. Several categories of pipe flow measurement devices will be described and discussed, including some associated calculations.

Flow Measurement in Pipes and Ducts

This course is about measurement of the flow rate of a fluid flowing under pressure in a closed conduit. The closed conduit is often circular, but also may be square or rectangular (such as a heating duct) or any other shape. The other major category of flow is open channel flow, which is the flow of a liquid with a free surface open to atmospheric pressure. Measurement of the flow rate of a fluid flowing under pressure, is carried out for a variety of purposes, such as billing for water supply to homes or businesses or, for monitoring or process control of a wide variety of industrial processes that involve flowing fluids. Several categories of pipe flow measurement devices will be described and discussed, including some associated calculations.