Wastewater Treatment

Efficiency And Sensitivity Of The Wet Oxidation/Biological Steps In Coupled Pharmaceutical Wastewater Treatment

Views : 6

Source: https://www.elsevier.com

Author: Sergio Collado, David Quero, Adriana Laca, Mario Díaz

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Wastewater Treatment

Only logged in customers who have purchased this product may leave a review.

Related books

Advanced wastewater treatment for separation and removal of pharmaceutical residues and other hazardous substances

The Swedish Environmental Protection Agency (EPA) has determined a need to introduce advanced treatment for pharmaceutical residues in wastewater. An additional benefit of such a treatment is that it would also include the treatment of other hazardous substances.The extent to which pharmaceutical residues risk becoming a problem depends on local conditions such as the sensitivity of the receiving waters. While this is an important variable to consider, the Swedish EPA believes that the sensitivity of the receiving waters should not be the only consideration when setting requirements for treatment. The amount of released pharmaceutical residues and long-term effects should also be considered in decision making and justification. The investment and operational costs of introducing advanced treatment depend in part on the size and current capacity of treatment facilities, which is why size limitations can be an additional consideration when setting requirements.

Advanced wastewater treatment for separation and removal of pharmaceutical residues and other hazardous substances

The Swedish Environmental Protection Agency (EPA) has determined a need to introduce advanced treatment for pharmaceutical residues in wastewater. An additional benefit of such a treatment is that it would also include the treatment of other hazardous substances.The extent to which pharmaceutical residues risk becoming a problem depends on local conditions such as the sensitivity of the receiving waters. While this is an important variable to consider, the Swedish EPA believes that the sensitivity of the receiving waters should not be the only consideration when setting requirements for treatment. The amount of released pharmaceutical residues and long-term effects should also be considered in decision making and justification. The investment and operational costs of introducing advanced treatment depend in part on the size and current capacity of treatment facilities, which is why size limitations can be an additional consideration when setting requirements.

Advanced Oxidation Processes for Water Treatment

This book provides an overview of the most studied AOPs, some of which are largely implemented for water remediation. The fundamental principles, kinetic modeling, water quality impact on process performance, byproduct formation, economics, examples of research and pilot studies, full-scale applications and future research needs are discussed for each advanced oxidation process.

Advanced Oxidation Processes for Water Treatment

This book provides an overview of the most studied AOPs, some of which are largely implemented for water remediation. The fundamental principles, kinetic modeling, water quality impact on process performance, byproduct formation, economics, examples of research and pilot studies, full-scale applications and future research needs are discussed for each advanced oxidation process.

A Ground-Breaking Innovation In Wastewater Treatment

The fashion industry contributes 20% of industrial water pollution With a high water footprint, massive chemical use and atmospheric, water and greenhouse gas (GHG) emissions, dyehouse operations are the most environmentally damaging component of the apparel supply chain2.Global brands are responding by requiring manufacturers to treat wastewater and reduce effluent. Paradoxically, conventional water treatment systems generate toxic sludge, trading water pollution for solid, chemical discharge that is landfilled and emits GHG – mostly methane.

A Ground-Breaking Innovation In Wastewater Treatment

The fashion industry contributes 20% of industrial water pollution With a high water footprint, massive chemical use and atmospheric, water and greenhouse gas (GHG) emissions, dyehouse operations are the most environmentally damaging component of the apparel supply chain2.Global brands are responding by requiring manufacturers to treat wastewater and reduce effluent. Paradoxically, conventional water treatment systems generate toxic sludge, trading water pollution for solid, chemical discharge that is landfilled and emits GHG – mostly methane.

Advanced Wastewater Treatment Technologies

Wastewater, also written as waste water, is any water that has been adversely affected in quality by anthropogenic influence. Wastewater can originate from a combination of domestic, industrial, commercial or agricultural activities, surface runoff or storm water, and from sewer inflow or infiltration. Municipal wastewater (also called sewage) is usually conveyed in a combined sewer or sanitary sewer, and treated at a wastewater treatment plant. Treated wastewater is discharged into receiving water via an effluent pipe. Wastewaters generated in areas without access to centralized sewer systems rely on on-site wastewater systems. These typically comprise a septic tank, drain field, and optionally an on-site treatment unit. The management of wastewater belongs to the overarching term sanitation, just like the management of human excreta, solid waste and storm water (drainage). Industrial wastewater is defined as any wastewater generated from any manufacturing,

processing, institutional, commercial, or agricultural operation, or any operation that discharges other

than domestic or sanitary wastewater.

Advanced Wastewater Treatment Technologies

Wastewater, also written as waste water, is any water that has been adversely affected in quality by anthropogenic influence. Wastewater can originate from a combination of domestic, industrial, commercial or agricultural activities, surface runoff or storm water, and from sewer inflow or infiltration. Municipal wastewater (also called sewage) is usually conveyed in a combined sewer or sanitary sewer, and treated at a wastewater treatment plant. Treated wastewater is discharged into receiving water via an effluent pipe. Wastewaters generated in areas without access to centralized sewer systems rely on on-site wastewater systems. These typically comprise a septic tank, drain field, and optionally an on-site treatment unit. The management of wastewater belongs to the overarching term sanitation, just like the management of human excreta, solid waste and storm water (drainage). Industrial wastewater is defined as any wastewater generated from any manufacturing,

processing, institutional, commercial, or agricultural operation, or any operation that discharges other

than domestic or sanitary wastewater.

Agricultural Wastewater Treatment

In many semiarid and arid countries, water is now becoming an increasingly limited resource and managers are forced to take into account sources of water that may be used economically and efficiently to encourage further development. Simultaneously, with the population increasing at a high rate, the requirement for increased production of food is apparent. The prospective for irrigation to increase both the agricultural productivity and living standards of the poor has long been acknowledged. Irrigated agriculture occupies nearly 17% of the total arable land in the world but the yield from this land includes about 34% of the world total. This perspective is even more distinct in arid areas like the Near East Region, where only 30% of the cultivated land is irrigated but it yields around 75% of total agricultural production. In the same area, more than 50% of the food necessities are imported and the increased rate in demand for the food surpasses the rate of an upsurge in agricultural production (Tunney et al., 2000).

Agricultural Wastewater Treatment

In many semiarid and arid countries, water is now becoming an increasingly limited resource and managers are forced to take into account sources of water that may be used economically and efficiently to encourage further development. Simultaneously, with the population increasing at a high rate, the requirement for increased production of food is apparent. The prospective for irrigation to increase both the agricultural productivity and living standards of the poor has long been acknowledged. Irrigated agriculture occupies nearly 17% of the total arable land in the world but the yield from this land includes about 34% of the world total. This perspective is even more distinct in arid areas like the Near East Region, where only 30% of the cultivated land is irrigated but it yields around 75% of total agricultural production. In the same area, more than 50% of the food necessities are imported and the increased rate in demand for the food surpasses the rate of an upsurge in agricultural production (Tunney et al., 2000).

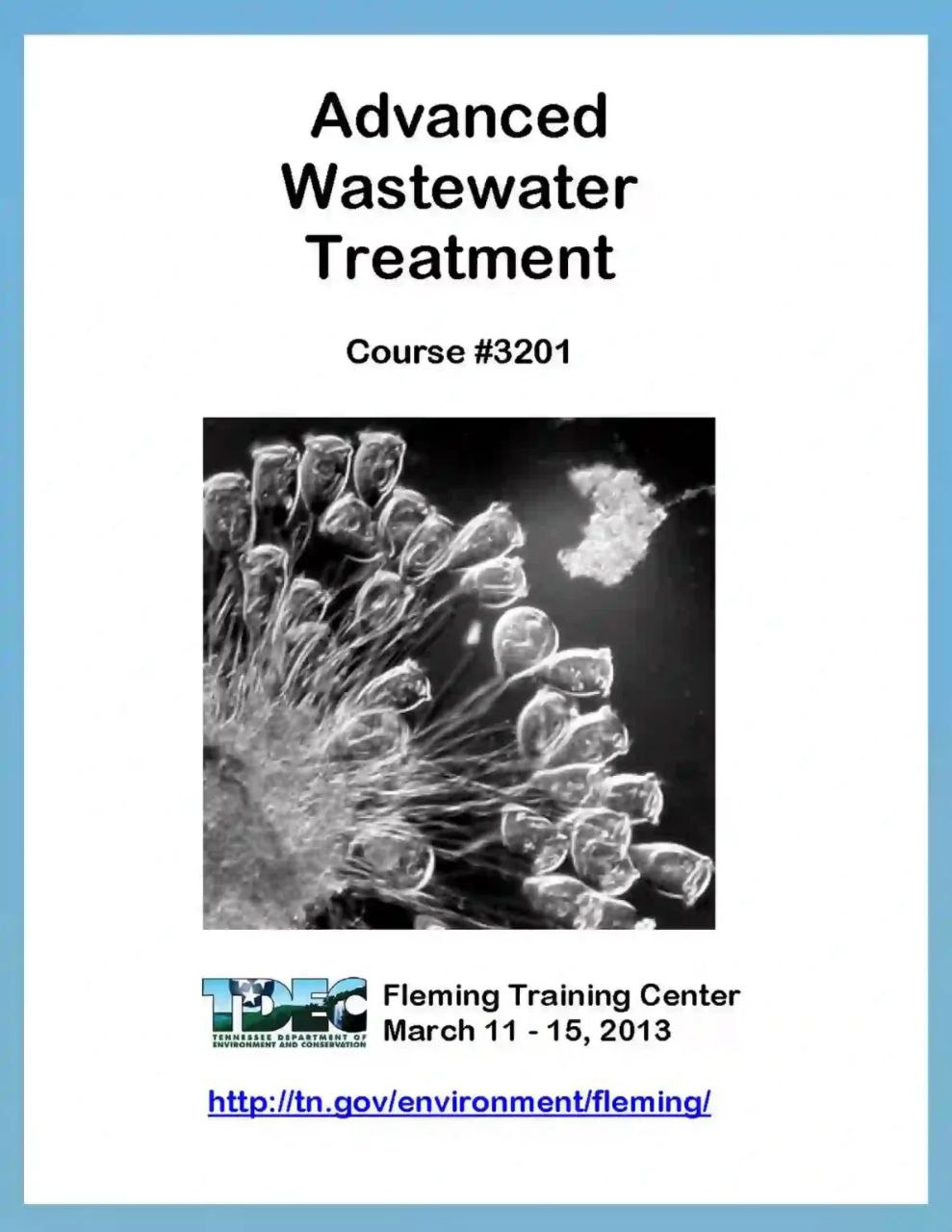

Discharge quality from municipal wastewater treatment plants and the Sludge Biotic Index for activated sludge: integrative assessment

Abstract

Wastewater treatment plants (WWTPs) are scrutinized by Environmental Authorities particularly regarding the compliance to discharge limit values fixed by national and local regulations. An integrated approach is necessary to achieve the objectives established with Directive 2000/60/EC (WFD) considering the ecological status of the receiving water body and the quality of the discharge. Specifically, documentary, technical, management and analytical controls should be developed. Moreover, integrative information on the behaviour of the activated sludge in the aeration tank can be useful for plant managers as well as for the regulating Authorities. The study presents the experience concerning WWTP regulation considering the analytic assessment of the discharge as well the monitoring of the Sludge Biotic Index (SBI) for activated sludge. Data from monitoring during the period 2008–14 on SBI values and chemical and microbiological data on the discharges of a sample of 35 WWTPs in the province of Venice (north-east Italy, Veneto region) are presented and discussed. Together with chemical and microbiological analysis, the SBI appears to be a highly useful index for the integrative assessment of plant functionality, in particular when monitoring and identifying critical situations that can determine the exceedance of discharge limit values. The SBI method, in an integrated control approach, can be used for small and medium sized WWTPs that only treat domestic wastewaters. In a case by case assessment this may even substitute part of the analytical monitoring carried out in the WWTPs' control process.

Discharge quality from municipal wastewater treatment plants and the Sludge Biotic Index for activated sludge: integrative assessment

Abstract

Wastewater treatment plants (WWTPs) are scrutinized by Environmental Authorities particularly regarding the compliance to discharge limit values fixed by national and local regulations. An integrated approach is necessary to achieve the objectives established with Directive 2000/60/EC (WFD) considering the ecological status of the receiving water body and the quality of the discharge. Specifically, documentary, technical, management and analytical controls should be developed. Moreover, integrative information on the behaviour of the activated sludge in the aeration tank can be useful for plant managers as well as for the regulating Authorities. The study presents the experience concerning WWTP regulation considering the analytic assessment of the discharge as well the monitoring of the Sludge Biotic Index (SBI) for activated sludge. Data from monitoring during the period 2008–14 on SBI values and chemical and microbiological data on the discharges of a sample of 35 WWTPs in the province of Venice (north-east Italy, Veneto region) are presented and discussed. Together with chemical and microbiological analysis, the SBI appears to be a highly useful index for the integrative assessment of plant functionality, in particular when monitoring and identifying critical situations that can determine the exceedance of discharge limit values. The SBI method, in an integrated control approach, can be used for small and medium sized WWTPs that only treat domestic wastewaters. In a case by case assessment this may even substitute part of the analytical monitoring carried out in the WWTPs' control process.

Reviews

There are no reviews yet.