Increase Pipeline Flow Efficiency

Increase Pipeline Flow Efficiency

Prepared By: Dževad Hadžihafizović

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Hydraulic , Piping & Fittings

Only logged in customers who have purchased this product may leave a review.

Related products

Inspect New Piping

Piping systems are like arteries and veins in the oil industry. Piping systems comprise of pipes, flanges, bolting, gaskets, valves etc. They also include pipe hangers, supporting elements and other items necessary to prevent over pressurization and over stressing of the pressure containing components. Hence, one can say that pipe section when fitted with valves and other mechanical equipment and properly supported by hangers and supports are called piping.

Inspect New Piping

Piping systems are like arteries and veins in the oil industry. Piping systems comprise of pipes, flanges, bolting, gaskets, valves etc. They also include pipe hangers, supporting elements and other items necessary to prevent over pressurization and over stressing of the pressure containing components. Hence, one can say that pipe section when fitted with valves and other mechanical equipment and properly supported by hangers and supports are called piping.

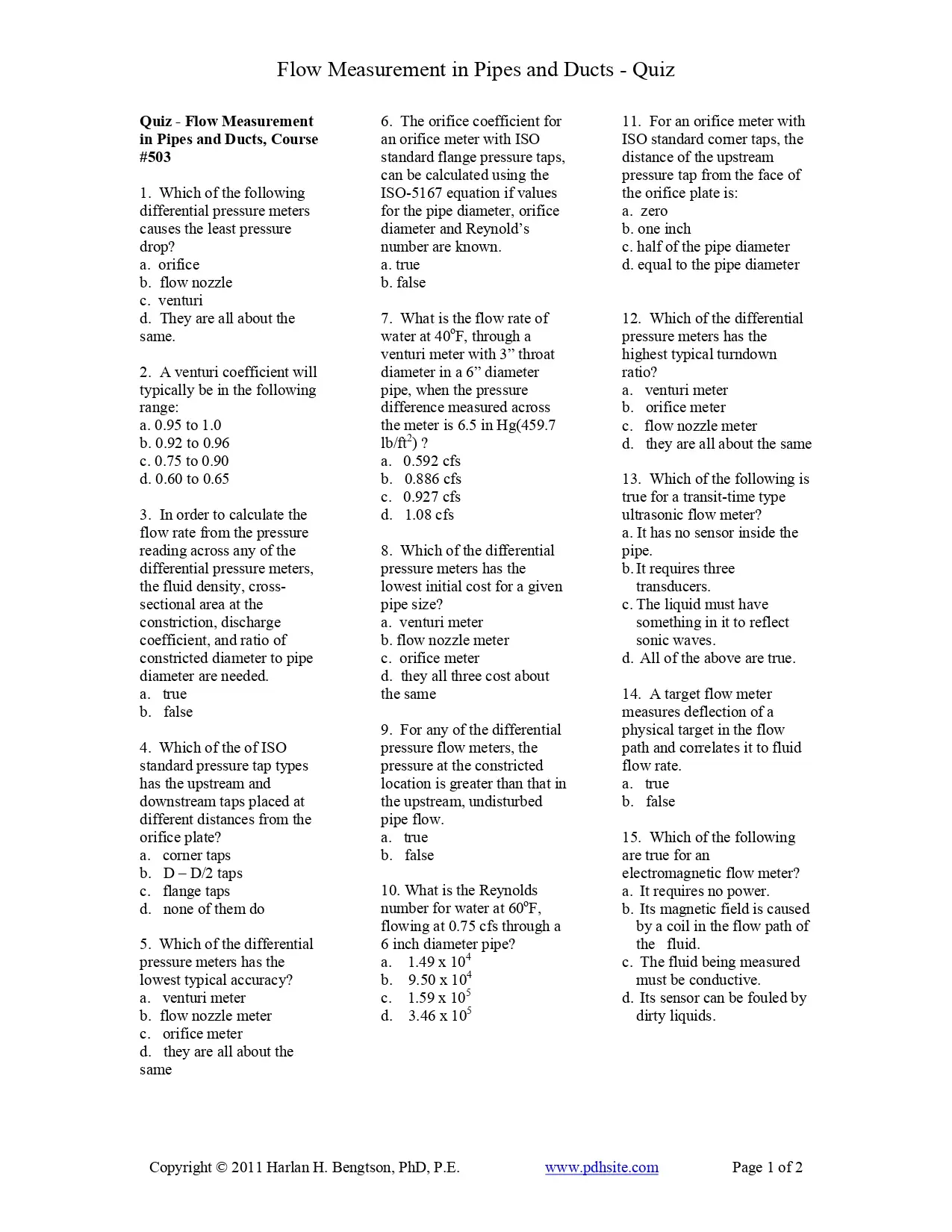

Pipe Flow-Friction Factor Calculations with Excel, Course

Several kinds of pipe flow calculations can be made with the Darcy- Weisbach equation and the Moody friction factor. These calculations can be conveniently carried out with an Excel spreadsheet. Many of the calculations require an iterative solution, so they are especially suitable for an Excel spreadsheet solution. This course includes discussion of the Darcy- Weisbach equation and the parameters in the equation along with the U.S.

and S.I. units to be used. Example calculations and sample Excel spreadsheets for making the calculations are also included. This course is intended primarily for civil engineers, mechanical engineers, chemical engineers, and environmental engineers. After completing this course you will be able to make calculations with the Darcy Weisbach equation and the Moody friction factor equations to calculate several different unknown parameters when sufficient input data is provided. You will also be prepared to use Excel spreadsheets to efficiently make the calculations.

Pipe Flow-Friction Factor Calculations with Excel, Course

Several kinds of pipe flow calculations can be made with the Darcy- Weisbach equation and the Moody friction factor. These calculations can be conveniently carried out with an Excel spreadsheet. Many of the calculations require an iterative solution, so they are especially suitable for an Excel spreadsheet solution. This course includes discussion of the Darcy- Weisbach equation and the parameters in the equation along with the U.S.

and S.I. units to be used. Example calculations and sample Excel spreadsheets for making the calculations are also included. This course is intended primarily for civil engineers, mechanical engineers, chemical engineers, and environmental engineers. After completing this course you will be able to make calculations with the Darcy Weisbach equation and the Moody friction factor equations to calculate several different unknown parameters when sufficient input data is provided. You will also be prepared to use Excel spreadsheets to efficiently make the calculations.

Cathodic Protection Part 1 – Pipelines

SA Water is responsible for operation and maintenance of an extensive network of buried pipelines. Cathodic Protection (CP) is applied to a large proportion of those buried assets which assists with the management of external pipeline corrosion and is therefore and an important asset management tool to greatly increase asset life. This Standard has been developed to assist in the design, maintenance, construction, and management of SA Water’s pipeline CP infrastructure. The purpose of this Standard is to detail the requirements for each phase of a pipeline CP project from design, construction and commissioning, to maintenance and monitoring to ensure a consistent approach is achieved independent of the delivery model of a project, its location, project ownership or other influences.

Cathodic Protection Part 1 – Pipelines

SA Water is responsible for operation and maintenance of an extensive network of buried pipelines. Cathodic Protection (CP) is applied to a large proportion of those buried assets which assists with the management of external pipeline corrosion and is therefore and an important asset management tool to greatly increase asset life. This Standard has been developed to assist in the design, maintenance, construction, and management of SA Water’s pipeline CP infrastructure. The purpose of this Standard is to detail the requirements for each phase of a pipeline CP project from design, construction and commissioning, to maintenance and monitoring to ensure a consistent approach is achieved independent of the delivery model of a project, its location, project ownership or other influences.

Reviews

There are no reviews yet.