Water Desalination & RO

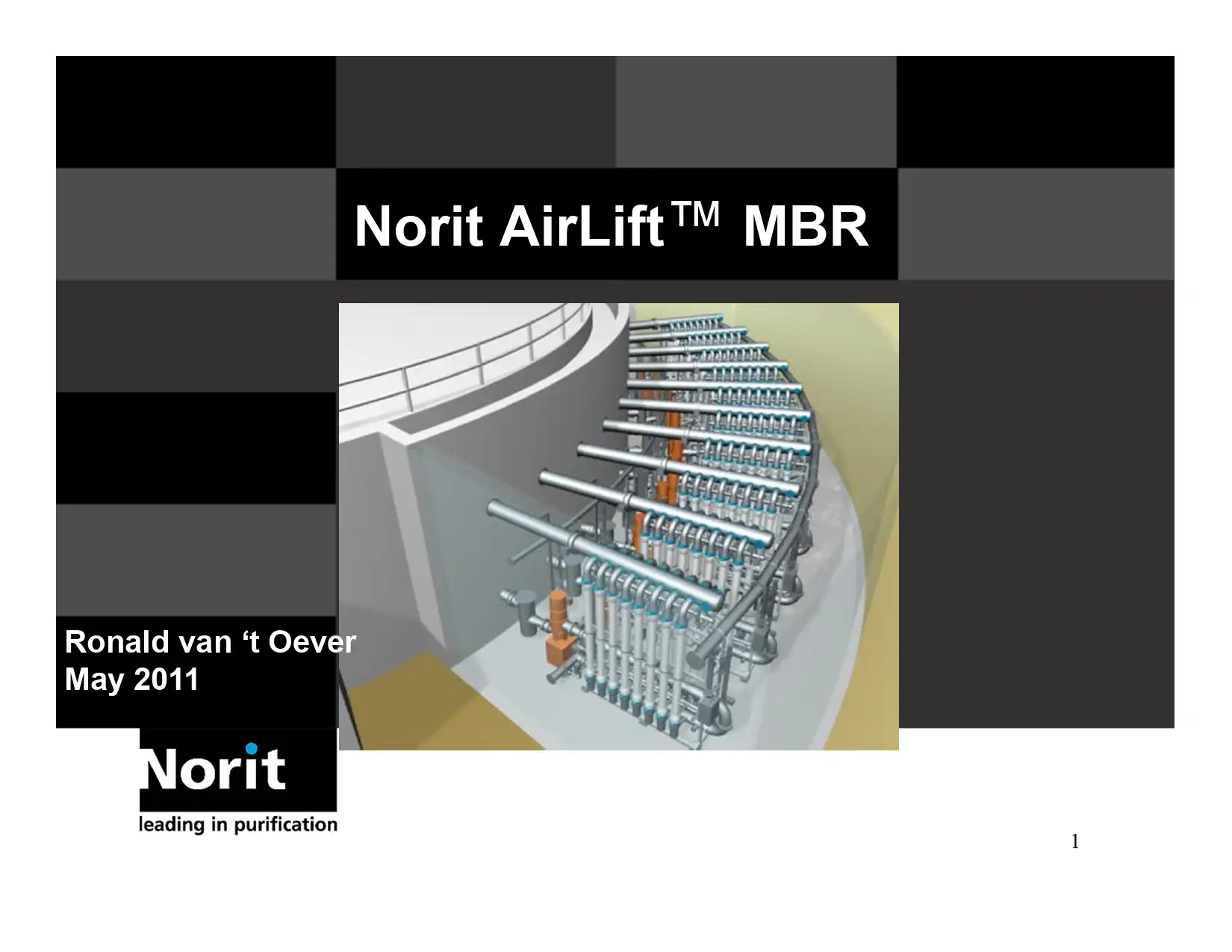

Norit AirLift™ MBR

Views : 12

Source: https://norit.com

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Water Desalination & RO

Only logged in customers who have purchased this product may leave a review.

Related books

Assessment Of Best Available Technologies For Desalination In Rural/Local Areas

Introduction: The Sustainable Water Integrated Management (SWIM) is a European Union(EU)-funded Regional Technical

Assistance Program [1] that “aims at supporting water governance and mainstreaming by promoting sustainable

and equitable water resources management to become a prominent feature of national development policies and

strategies (agriculture, industry, tourism, etc).” [2]

Countries in the south of the Mediterranean are facing increasing water scarcity. This scarcity is driving the need

for augmenting conventional water supply with alternative water sources. Rural and remote areas are particularly

disadvantaged because such areas are often located far away from municipal water supply systems and

conventional water sources, and are often not connected to the electric power grid. There is good potential for

addressing the water scarcity problem in rural and remote areas through sustainable saline water desalination

technologies. Seawater and brackish water desalination are well-established industries comprising a wide variety

of available technologies with decades of accumulated experience. There are many advancements and evolution in

desalination technologies. The numerous technologies and processes available have different characteristics,

advantages and disadvantages that make each suitable for particular market segments or specific niches.

Moreover, much of the cumulative technology experience is related to large urban supply plants that are either

connected to the grid, or are themselves part of large power and desalination cogeneration plants. Rural and

remote areas have special requirements that influence the appropriate selection of technologies. These include

technical requirements related to small-scale application using renewable energy sources, ease of operation and

maintenance, and simple design; requirements dictated by geographical location; as well as socio-economic and

socio-cultural requirements related to the communities that are intended to operate and benefit from the

technology. Successful implementation and long term sustainability (operational and environmental sustainability)

of desalination projects for rural and remote locations requires that all the relevant requirements be identified and

addressed from the earliest stages of the project.

Assessment Of Best Available Technologies For Desalination In Rural/Local Areas

Introduction: The Sustainable Water Integrated Management (SWIM) is a European Union(EU)-funded Regional Technical

Assistance Program [1] that “aims at supporting water governance and mainstreaming by promoting sustainable

and equitable water resources management to become a prominent feature of national development policies and

strategies (agriculture, industry, tourism, etc).” [2]

Countries in the south of the Mediterranean are facing increasing water scarcity. This scarcity is driving the need

for augmenting conventional water supply with alternative water sources. Rural and remote areas are particularly

disadvantaged because such areas are often located far away from municipal water supply systems and

conventional water sources, and are often not connected to the electric power grid. There is good potential for

addressing the water scarcity problem in rural and remote areas through sustainable saline water desalination

technologies. Seawater and brackish water desalination are well-established industries comprising a wide variety

of available technologies with decades of accumulated experience. There are many advancements and evolution in

desalination technologies. The numerous technologies and processes available have different characteristics,

advantages and disadvantages that make each suitable for particular market segments or specific niches.

Moreover, much of the cumulative technology experience is related to large urban supply plants that are either

connected to the grid, or are themselves part of large power and desalination cogeneration plants. Rural and

remote areas have special requirements that influence the appropriate selection of technologies. These include

technical requirements related to small-scale application using renewable energy sources, ease of operation and

maintenance, and simple design; requirements dictated by geographical location; as well as socio-economic and

socio-cultural requirements related to the communities that are intended to operate and benefit from the

technology. Successful implementation and long term sustainability (operational and environmental sustainability)

of desalination projects for rural and remote locations requires that all the relevant requirements be identified and

addressed from the earliest stages of the project.

A Primer On Brackish And Seawater Desalination

Abstract: This publication was produced as an activity of the Texas Living Waters Project. This project

is a collaborative effort of the National Wildlife Federation, Environmental Defense, and the Lone

Star Chapter of the Sierra Club. The goals of the project are to 1) ensure adequate water for people

and environmental needs, 2) reduce future demand for water and foster efficient and sustainable use

of current water supplies, 3) educate the public and decision makers about the impact of wasteful

water use and the opportunities for water conservation, and 4) involve citizens in the decision

making process for water management.

A Primer On Brackish And Seawater Desalination

Abstract: This publication was produced as an activity of the Texas Living Waters Project. This project

is a collaborative effort of the National Wildlife Federation, Environmental Defense, and the Lone

Star Chapter of the Sierra Club. The goals of the project are to 1) ensure adequate water for people

and environmental needs, 2) reduce future demand for water and foster efficient and sustainable use

of current water supplies, 3) educate the public and decision makers about the impact of wasteful

water use and the opportunities for water conservation, and 4) involve citizens in the decision

making process for water management.

Desalination and Water Treatment

Abstract:

This study proposes a simple design method of the Reverse osmosis (RO) system in RO brackish water desalination plants. This method is based on the application of maximum available recovery without scaling of any of the compounds present in the water as silica, calcium carbonate, calcium sulfate, barium sulfate, strontium sulfate, and calcium fluoride, and membrane manufacturer design guidelines, and the plant production. Although the method was originally

conceived for application to subterranean brackish waters in the Canary Islands, Spain (principally Gran Canaria, Fuerteventura and Tenerife), it can be extrapolated to other types of region and water treatable with RO systems. The required input data are the chemical composition of the feed water, pH, temperature, silt density index membrane manufacturer design guidelines, and the plant production. The programmed method then determines the design of the RO system. The method whose procedure is described graphically and analytically can be used as an aid in design optimization of RO brackish water desalination plants with acid-free pretreatment processes and only the use of scale inhibitor using spiral wound membranes. Practical applications are presented. The final results for different types of feed water and capacities are showed.

Desalination and Water Treatment

Abstract:

This study proposes a simple design method of the Reverse osmosis (RO) system in RO brackish water desalination plants. This method is based on the application of maximum available recovery without scaling of any of the compounds present in the water as silica, calcium carbonate, calcium sulfate, barium sulfate, strontium sulfate, and calcium fluoride, and membrane manufacturer design guidelines, and the plant production. Although the method was originally

conceived for application to subterranean brackish waters in the Canary Islands, Spain (principally Gran Canaria, Fuerteventura and Tenerife), it can be extrapolated to other types of region and water treatable with RO systems. The required input data are the chemical composition of the feed water, pH, temperature, silt density index membrane manufacturer design guidelines, and the plant production. The programmed method then determines the design of the RO system. The method whose procedure is described graphically and analytically can be used as an aid in design optimization of RO brackish water desalination plants with acid-free pretreatment processes and only the use of scale inhibitor using spiral wound membranes. Practical applications are presented. The final results for different types of feed water and capacities are showed.

Desalination: A National Perspective

NOTICE:

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The members of the panel responsible for the report were chosen for their special competences and with regard for appropriate balance.

Support for this study was provided by the U.S. Bureau of Reclamation under Grant No. 06CS811198. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the organizations or agencies that provided

support for the project.

Desalination: A National Perspective

NOTICE:

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The members of the panel responsible for the report were chosen for their special competences and with regard for appropriate balance.

Support for this study was provided by the U.S. Bureau of Reclamation under Grant No. 06CS811198. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the organizations or agencies that provided

support for the project.

Desalination At A Glance

Introduction:

By desalination, we will be referring to the production of a useful product water from a feed

water that is too high in inorganic materials (salts) to be useful. The feed water may be

seawater, brackish water, or other “impaired” water that cannot be used directly for potable

or general industrial purposes. Notice that this definition includes the treatment of certain

wastewaters for subsequent reuse.

The principal technologies used in desalination are based on concepts that are fairly easy to

grasp by those with a modest amount of scientific training and/or technical experience. In

practice, however, choices of technology and plant design are usually determined by factors

that might appear minor to the inexperienced. Similarly, new technologies that show great

promise in the laboratory frequently fail for reasons that were earlier overlooked or dismissed

as trivial. Indeed, professional fascination with specific technical elegance has, in some

cases, led researchers to remain oblivious to inherent limitations of a process. Nonetheless,

attention to detail over the past five decades has resulted in dramatic reductions in capital

and operating costs as well as greatly increased plant reliability and performance

Desalination At A Glance

Introduction:

By desalination, we will be referring to the production of a useful product water from a feed

water that is too high in inorganic materials (salts) to be useful. The feed water may be

seawater, brackish water, or other “impaired” water that cannot be used directly for potable

or general industrial purposes. Notice that this definition includes the treatment of certain

wastewaters for subsequent reuse.

The principal technologies used in desalination are based on concepts that are fairly easy to

grasp by those with a modest amount of scientific training and/or technical experience. In

practice, however, choices of technology and plant design are usually determined by factors

that might appear minor to the inexperienced. Similarly, new technologies that show great

promise in the laboratory frequently fail for reasons that were earlier overlooked or dismissed

as trivial. Indeed, professional fascination with specific technical elegance has, in some

cases, led researchers to remain oblivious to inherent limitations of a process. Nonetheless,

attention to detail over the past five decades has resulted in dramatic reductions in capital

and operating costs as well as greatly increased plant reliability and performance

Desalination & Water Purification Technologies

Introduction:

The world’s water consumption rate is doubling every 20 years, outpacing by two times the rate of population growth. The availability of good quality water is on the decline and water demand is on the rise. Worldwide availability of fresh water for industrial needs and human consumption is limited.

Various industrial and developmental activities in recent times have resulted in increasing the pollution level and deteriorating the water quality. Water shortages and unreliable water quality are considered major obstacles to achieve sustainable development and improvement in the quality of life. The water

demand in the country is increasing fast due to progressive increase in the demand of water for irrigation, rapid industrialization, and population growth and improving life standards. The existing water resources are diminishing (i) due to unequal distribution of rain water and occasional drought, (ii) excessive exploitation of ground water sources and its insufficient recharge, (iii) deterioration of water quality due to the discharge of domestic and industrial effluents without adequate treatment. This is resulting into water stress/ scarcity. Country is currently passing through social and economic transition.

The proportion of the population which is urban has doubled over the last thirty years (and is now about 30%), agriculture now accounts for about 25% of GDP and the economy has been growing at around 7-9% a year. Country has a highly seasonal pattern of rainfall, with 50% of precipitation falling

in just 15 days and over 90% of river flows in just four months

Desalination & Water Purification Technologies

Introduction:

The world’s water consumption rate is doubling every 20 years, outpacing by two times the rate of population growth. The availability of good quality water is on the decline and water demand is on the rise. Worldwide availability of fresh water for industrial needs and human consumption is limited.

Various industrial and developmental activities in recent times have resulted in increasing the pollution level and deteriorating the water quality. Water shortages and unreliable water quality are considered major obstacles to achieve sustainable development and improvement in the quality of life. The water

demand in the country is increasing fast due to progressive increase in the demand of water for irrigation, rapid industrialization, and population growth and improving life standards. The existing water resources are diminishing (i) due to unequal distribution of rain water and occasional drought, (ii) excessive exploitation of ground water sources and its insufficient recharge, (iii) deterioration of water quality due to the discharge of domestic and industrial effluents without adequate treatment. This is resulting into water stress/ scarcity. Country is currently passing through social and economic transition.

The proportion of the population which is urban has doubled over the last thirty years (and is now about 30%), agriculture now accounts for about 25% of GDP and the economy has been growing at around 7-9% a year. Country has a highly seasonal pattern of rainfall, with 50% of precipitation falling

in just 15 days and over 90% of river flows in just four months

Advanced Reverse Osmosis System Design

Overview of Advanced RO Design

• RO system design guideline variables

• Drivers for RO system configuration selection

• Principles and benefits of RO array flux balancing

• Array selection criteria to achieve permeate quality target

• Energy recovery

Advanced Reverse Osmosis System Design

Overview of Advanced RO Design

• RO system design guideline variables

• Drivers for RO system configuration selection

• Principles and benefits of RO array flux balancing

• Array selection criteria to achieve permeate quality target

• Energy recovery

Reviews

There are no reviews yet.