Electrical & Automation

Testing And Commissioning Procedures For Electrical Components And Equipments In Power Industries

Views : 7

Testing And Commissioning Procedures For Electrical Components And Equipments In Power Industries

Source: http://www.bemcosteel.com.sa

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Electrical & Automation

Only logged in customers who have purchased this product may leave a review.

Related books

Design Calculations for Electrical Design

Introduction:

Design calculations establish minimum guidelines and requirements for generating electrical calculations on projects. Electrical calculations should be made for all SPU projects that include electrical components and should be filed in the project notebook. Design calculations may be made either manually or by SPU-approved computer programs

Design Calculations for Electrical Design

Introduction:

Design calculations establish minimum guidelines and requirements for generating electrical calculations on projects. Electrical calculations should be made for all SPU projects that include electrical components and should be filed in the project notebook. Design calculations may be made either manually or by SPU-approved computer programs

VFD Smart Drive Technology Saving Electric Motor Energy

Electric Motors Use 70% of the World’s Power

■ We impact that load 30 – 50%

■ Savings can be as much as 20% to 30% on the overall bill

■ Look for 1hp and above operating at least 2,000 hrs/yr

VFD Smart Drive Technology Saving Electric Motor Energy

Electric Motors Use 70% of the World’s Power

■ We impact that load 30 – 50%

■ Savings can be as much as 20% to 30% on the overall bill

■ Look for 1hp and above operating at least 2,000 hrs/yr

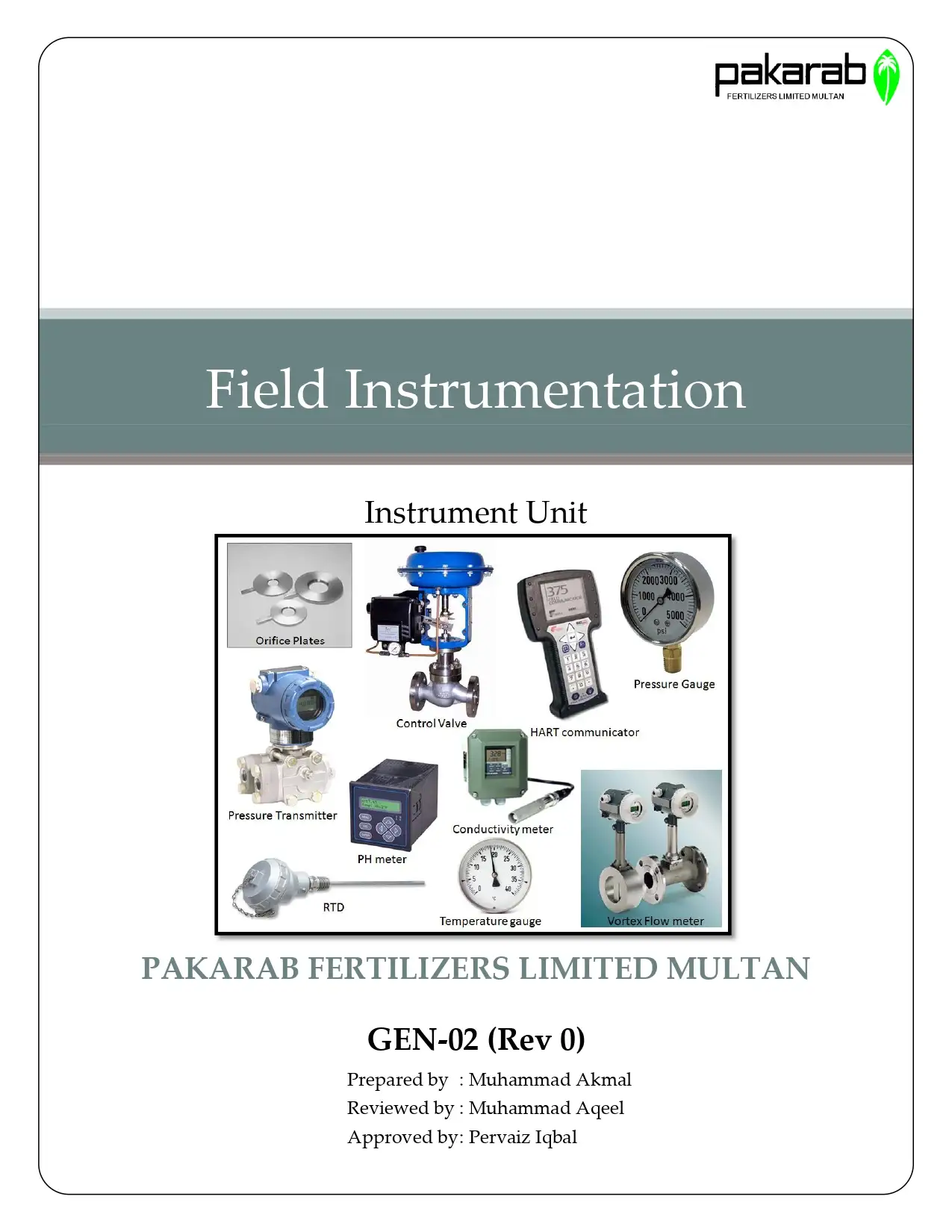

Field Instrumentation

Basic terms related to temperature

Different scales conversion

Basic temperature measuring techniques

RTD’s and its application

Thermocouples and their applications

Comparison between RTDs and Thermocouples

State the effect on the indicated temperature for failures, open circuits, and short

circuit

Field Instrumentation

Basic terms related to temperature

Different scales conversion

Basic temperature measuring techniques

RTD’s and its application

Thermocouples and their applications

Comparison between RTDs and Thermocouples

State the effect on the indicated temperature for failures, open circuits, and short

circuit

SCADA Systems Hardware(And FirmWare)

. Introduction

This chapter introduces the fundamental concepts of DCS systems. The terms Supervisory Control and Data Acquisition (SCADA), Distributed Control System (DCS), Programmable Logic Controller (PLC), and Smart Instrument are defined and placed in the context used in this manual. The chapter is split into the following sections:

Definitions of the terms SCADA, DCS, PLC and smart instrument

Remote terminal unit (RTU) structure

PLCs used as RTUs

System reliability and availability

Communication architectures and philosophies

Typical considerations in configuration of a master station

SCADA Systems Hardware(And FirmWare)

. Introduction

This chapter introduces the fundamental concepts of DCS systems. The terms Supervisory Control and Data Acquisition (SCADA), Distributed Control System (DCS), Programmable Logic Controller (PLC), and Smart Instrument are defined and placed in the context used in this manual. The chapter is split into the following sections:

Definitions of the terms SCADA, DCS, PLC and smart instrument

Remote terminal unit (RTU) structure

PLCs used as RTUs

System reliability and availability

Communication architectures and philosophies

Typical considerations in configuration of a master station

Using EDI to Meet the Needs of Pure Water Production

Summary

This report describes the advantages of using EDI for ultrapure water production for power plant boiler makeup water and microelectronics fabrication rinse water. Operating data is presented showing the advantages of EDI for these applications.

Using EDI to Meet the Needs of Pure Water Production

Summary

This report describes the advantages of using EDI for ultrapure water production for power plant boiler makeup water and microelectronics fabrication rinse water. Operating data is presented showing the advantages of EDI for these applications.

Reviews

There are no reviews yet.