Pumps & Mechanical

Training Module On Operation And Maintenance Of Pumps In Rural Water Supply Systems

Views : 5

Training Module On Operation And Maintenance Of Pumps In Rural Water Supply Systems

Source: https://www.mininfra.gov.rw

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Pumps & Mechanical

In general, a water supply system consists of infrastructure for catchment, for treatment, for storage, for pumping and for distribution of potable water. Infrastructure for pumping is only necessary when natural elevations of the area are not enough to overcome energy losses. If water is produced on a high location the water can flow by gravity to the consumers.

Only logged in customers who have purchased this product may leave a review.

Related books

Chapter One Introduction To Reciprocating Compressors

Introduction

Compressors are used whenever it is necessary to flow gas from a low-pressure system to a higher-pressure system. Flash gas from low-pressure vessels used for multi-stage stabilization of liquids, oil treating, water treating, etc.; often exists at too low a pressure to flow into the gas sales pipeline. Sometimes this gas is used as fuel, and them the remainder is flared or vented. In many instances, it is economically attractive to compress this gas to a high enough pressure so it can be sold. Compression may also be required for environmental reasons. Flash gas that might otherwise be flared may be compressed for sales or gas produced with oil (associated gas) may be compressed for re-injection to avoid, flaring or to help maintain reservoir pressure. In some marginal gas fields, and in many larger gas fields that experience a decline in flowing pressure with time, it may be economical to allow the wells to flow at surface pressures below that required for gas sales. In such cases, a booster compressor (one where the ratio of discharge to suction pressure is low) may be installed. Booster compressors are also used on long pipelines to restore pressure drop lost to friction. The use of large compressors is probably more prevalent in oil field facilities than in gas field facilities. Oil wells often require low flowing surface pressures and the gas that flashes off the oil in the separator must be compressed. Often, natural gas is, injected into the tubing of the well to lighten the column of liquid and reduce downhole pressure. This "gas lift" gas is produced back with good fluids at low pressure. Compressors are used so the lift gas can be recirculated and

Chapter One Introduction To Reciprocating Compressors

Introduction

Compressors are used whenever it is necessary to flow gas from a low-pressure system to a higher-pressure system. Flash gas from low-pressure vessels used for multi-stage stabilization of liquids, oil treating, water treating, etc.; often exists at too low a pressure to flow into the gas sales pipeline. Sometimes this gas is used as fuel, and them the remainder is flared or vented. In many instances, it is economically attractive to compress this gas to a high enough pressure so it can be sold. Compression may also be required for environmental reasons. Flash gas that might otherwise be flared may be compressed for sales or gas produced with oil (associated gas) may be compressed for re-injection to avoid, flaring or to help maintain reservoir pressure. In some marginal gas fields, and in many larger gas fields that experience a decline in flowing pressure with time, it may be economical to allow the wells to flow at surface pressures below that required for gas sales. In such cases, a booster compressor (one where the ratio of discharge to suction pressure is low) may be installed. Booster compressors are also used on long pipelines to restore pressure drop lost to friction. The use of large compressors is probably more prevalent in oil field facilities than in gas field facilities. Oil wells often require low flowing surface pressures and the gas that flashes off the oil in the separator must be compressed. Often, natural gas is, injected into the tubing of the well to lighten the column of liquid and reduce downhole pressure. This "gas lift" gas is produced back with good fluids at low pressure. Compressors are used so the lift gas can be recirculated and

Chapter Two Reciprocating Compressors Construction Details

Reciprocating Compressors Construction Details

In general, materials for the construction of the compressor and auxiliaries are normally the manufacturer's standard for the specified operating conditions except as required by the datasheet or certain specifications.

Chapter Two Reciprocating Compressors Construction Details

Reciprocating Compressors Construction Details

In general, materials for the construction of the compressor and auxiliaries are normally the manufacturer's standard for the specified operating conditions except as required by the datasheet or certain specifications.

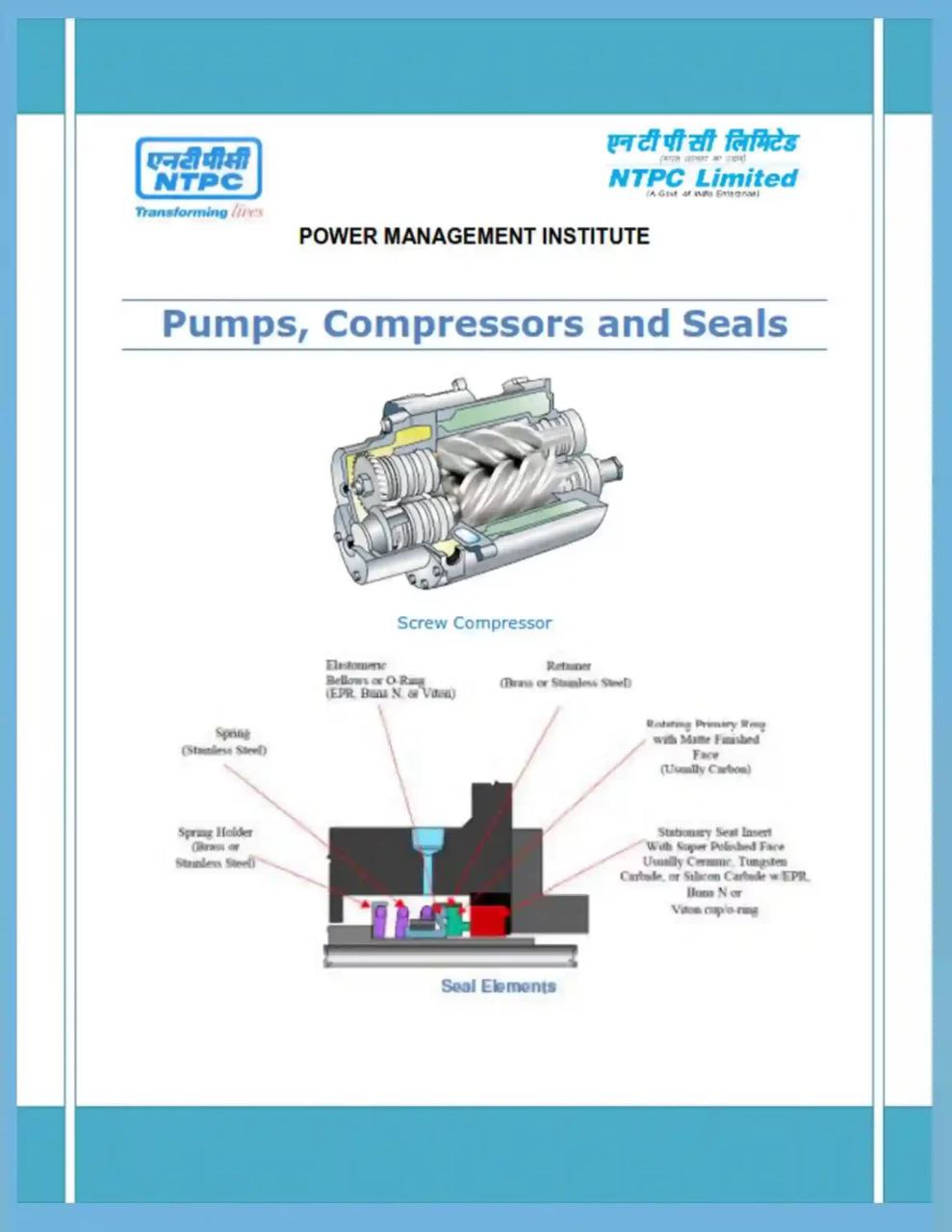

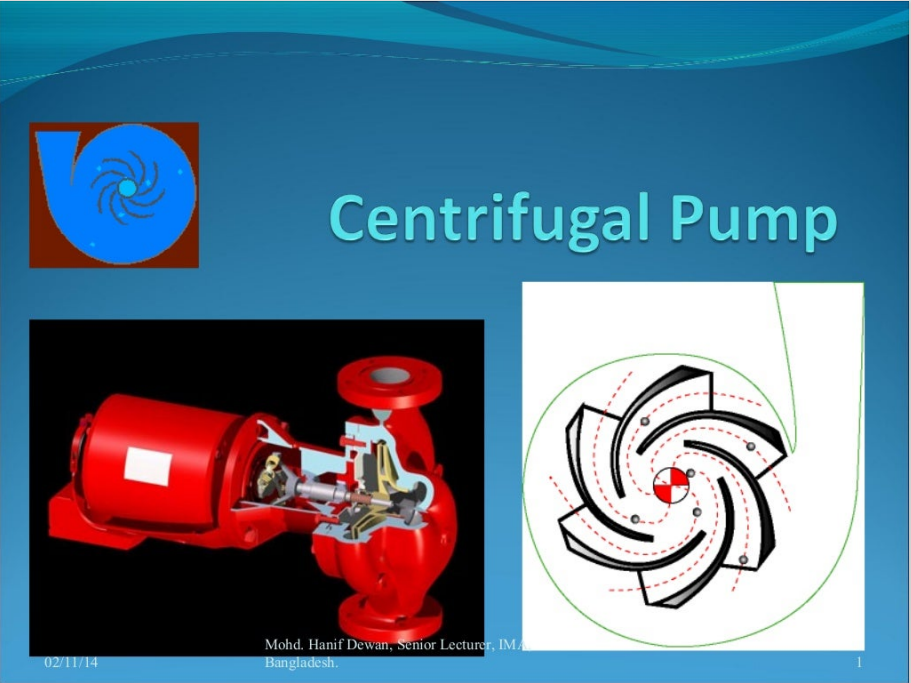

Pumps, Compressors and Seals

The most numerous types of fluid machineries are of the pump family (machines which add energy to the fluid), other important types are turbines (which extract energy from fluid). Both types are usually connected to a rotating shaft, hence also called turbomachineries. The prefix turbo- is a Latin word meaning ―spin’’ or ―whirl,’’ appropriate for rotating devices. The pump is the oldest fluid-energy-transfer device known. At least two designs date before Christ: (i) the undershot-bucket waterwheels, or norias, used in Asia and Africa (1000 B.C.) and (ii) Archimedes’ screw pump (250 B.C.), still being manufactured today to handle solid-liquid mixtures or to raise water from the hold of a ship. Paddlewheel turbines were used by the Romans in 70 B.C., and Babylonian windmills date back to 700 B.C. Since that time, many variations and applications of pumps have been developed. The power generating turbomachines (turbines) decrease the head or energy level of the working fluids passing through them and they are coupled to machines, such as electric generators, pumps, compressors etc.

Pumps, Compressors and Seals

The most numerous types of fluid machineries are of the pump family (machines which add energy to the fluid), other important types are turbines (which extract energy from fluid). Both types are usually connected to a rotating shaft, hence also called turbomachineries. The prefix turbo- is a Latin word meaning ―spin’’ or ―whirl,’’ appropriate for rotating devices. The pump is the oldest fluid-energy-transfer device known. At least two designs date before Christ: (i) the undershot-bucket waterwheels, or norias, used in Asia and Africa (1000 B.C.) and (ii) Archimedes’ screw pump (250 B.C.), still being manufactured today to handle solid-liquid mixtures or to raise water from the hold of a ship. Paddlewheel turbines were used by the Romans in 70 B.C., and Babylonian windmills date back to 700 B.C. Since that time, many variations and applications of pumps have been developed. The power generating turbomachines (turbines) decrease the head or energy level of the working fluids passing through them and they are coupled to machines, such as electric generators, pumps, compressors etc.

Fire Pump Systems Design and Specification

Think your fire pumps are just like the rest of your fluid movers? Think again. Rigorous standards and certifications make sure these life-savers are up to snuff

Fire Pump Systems Design and Specification

Think your fire pumps are just like the rest of your fluid movers? Think again. Rigorous standards and certifications make sure these life-savers are up to snuff

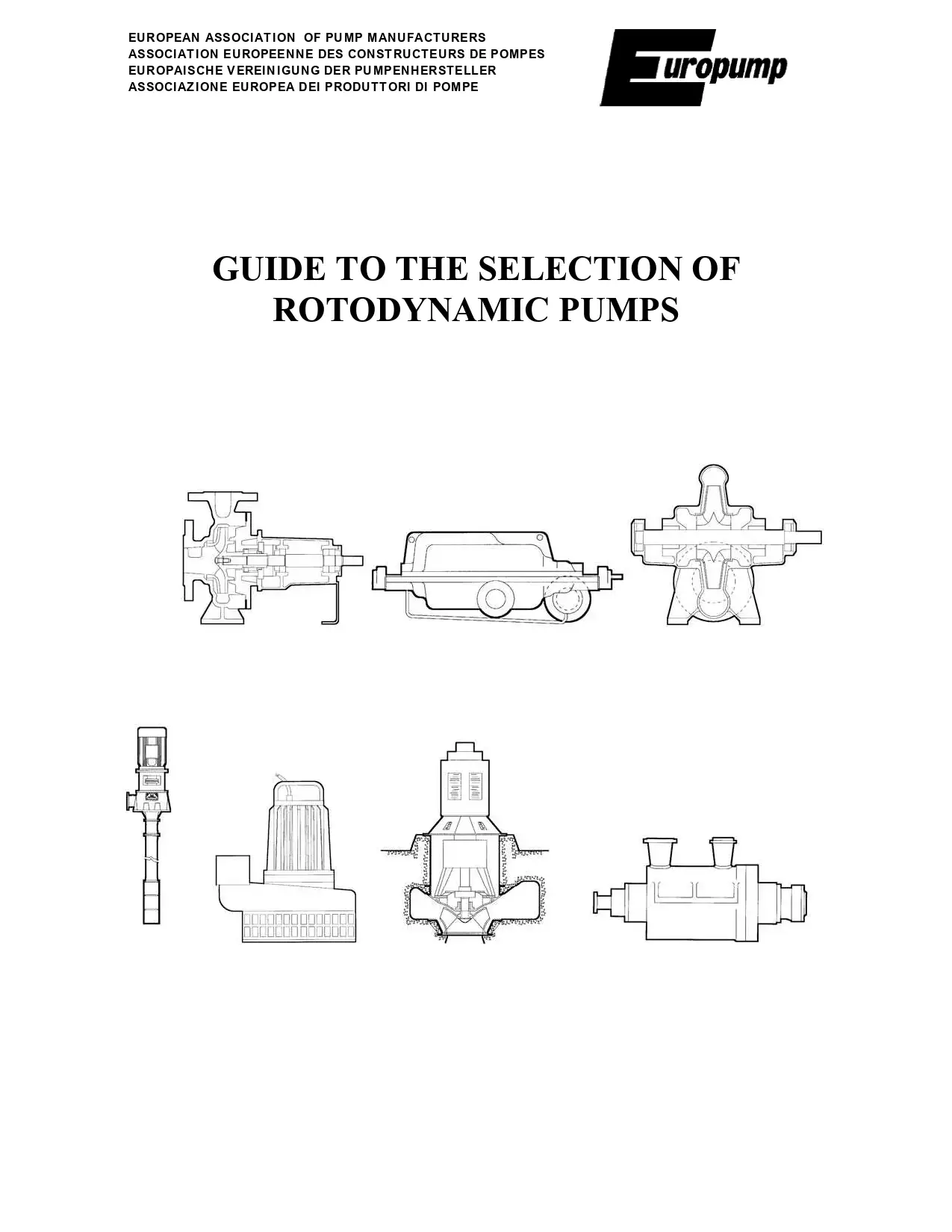

Guide To The Selection Of Rotodynamic Pumps

Purpose of this Guide to pump procurement

This Guide provides an introduction to the very complex subject of the selection of pumps. It is aimed at anyone who wishes to purchase or select a pump and, at the same time, wishes to save money on their energy bill. Almost invariably, this saving will be far more than the first cost of the pump. The reader may be the end user, a contractor, or a consultant. This Guide provides the reader with the basic principles of pump procurement, giving pointers to the pump type and performance they should consider. Pumps are divided into their main types, then their basic construction and performance are considered, their principal applications are described, the basic principles of pump selection are explained and, last but not least, target efficiencies are set to help minimize energy usage. The hope is that both pump users and the environment will benefit.

Guide To The Selection Of Rotodynamic Pumps

Purpose of this Guide to pump procurement

This Guide provides an introduction to the very complex subject of the selection of pumps. It is aimed at anyone who wishes to purchase or select a pump and, at the same time, wishes to save money on their energy bill. Almost invariably, this saving will be far more than the first cost of the pump. The reader may be the end user, a contractor, or a consultant. This Guide provides the reader with the basic principles of pump procurement, giving pointers to the pump type and performance they should consider. Pumps are divided into their main types, then their basic construction and performance are considered, their principal applications are described, the basic principles of pump selection are explained and, last but not least, target efficiencies are set to help minimize energy usage. The hope is that both pump users and the environment will benefit.

Reviews

There are no reviews yet.