RO/NF Process Design

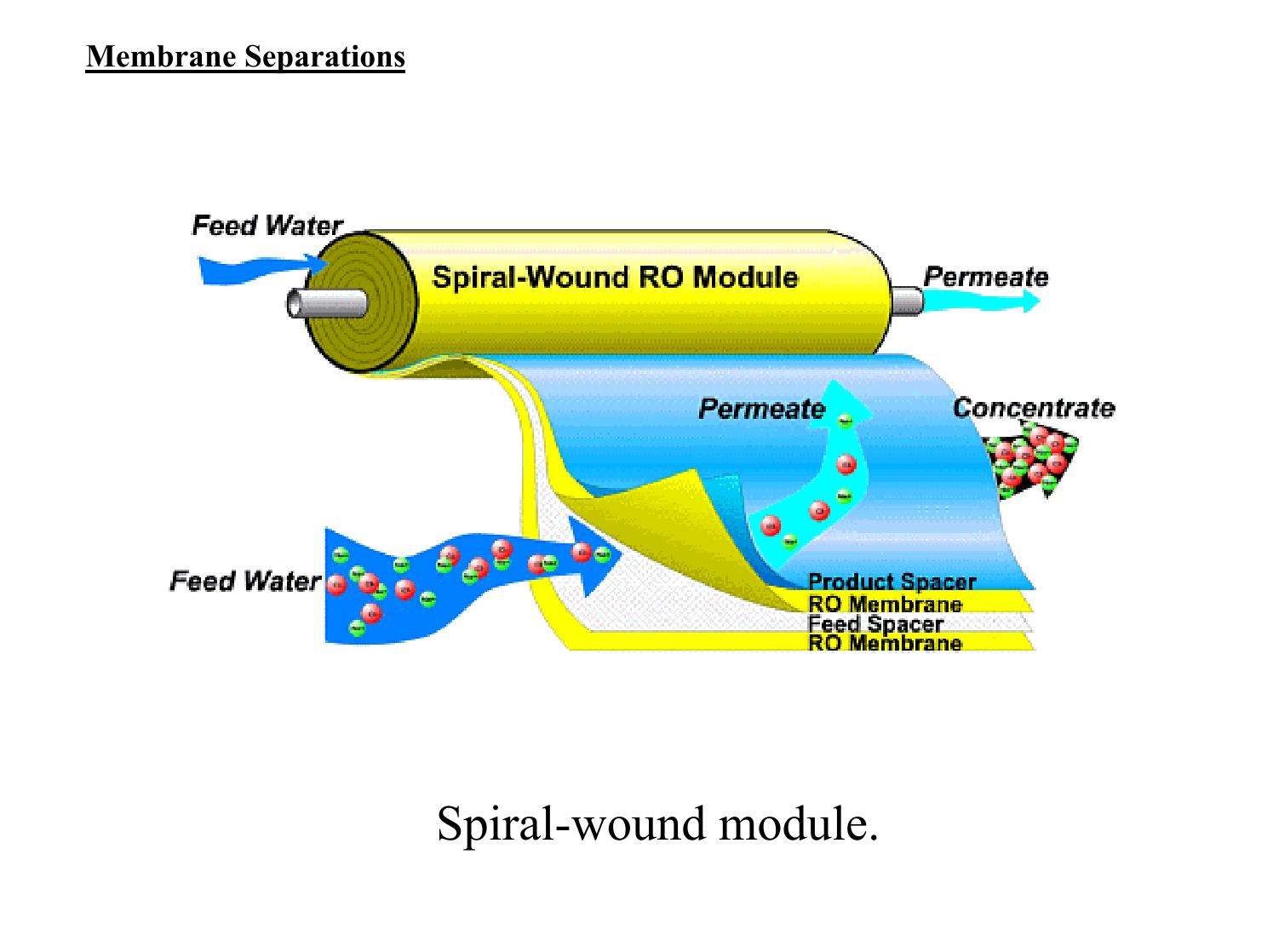

RO / NF system is usually designed for continuous operation and the operating conditions of every membrane element in the plant are constant with time. In certain applications, however, a batch operation mode is used in treating wastewater or industrial process solutions when relatively small volumes (batches) of feed water are discharged non-continuously. The feed water is collected in a tank and then periodically treated. A modification of the batch mode is the semi-batch mode, where the feed tank is refilled with feed water during operation. A permeate staged (double pass) system is the combination of two conventional RO systems where permeate of the first system (first pass) becomes the feed for the second system (second pass). Both RO / NF systems may be of the single-stage or multi-stage type, either with plug flow or with concentrate recirculation. The production of water for pharmaceutical and medical use are typical applications of permeate staged systems. As an alternative to a second pass, ion exchange may also be considered.

RO/NF Process Design

RO / NF system is usually designed for continuous operation and the operating conditions of every membrane element in the plant are constant with time. In certain applications, however, a batch operation mode is used in treating wastewater or industrial process solutions when relatively small volumes (batches) of feed water are discharged non-continuously. The feed water is collected in a tank and then periodically treated. A modification of the batch mode is the semi-batch mode, where the feed tank is refilled with feed water during operation. A permeate staged (double pass) system is the combination of two conventional RO systems where permeate of the first system (first pass) becomes the feed for the second system (second pass). Both RO / NF systems may be of the single-stage or multi-stage type, either with plug flow or with concentrate recirculation. The production of water for pharmaceutical and medical use are typical applications of permeate staged systems. As an alternative to a second pass, ion exchange may also be considered.