Water Desalination & RO

Smart Water Network: New Technologies for Intelligent Urban Water Infrastructure

Views : 23

Usually dispatched in 2 to 3 days

Usually dispatched in 2 to 3 days

Category:

Water Desalination & RO

Only logged in customers who have purchased this product may leave a review.

Related books

A Primer On Brackish And Seawater Desalination

Abstract: This publication was produced as an activity of the Texas Living Waters Project. This project

is a collaborative effort of the National Wildlife Federation, Environmental Defense, and the Lone

Star Chapter of the Sierra Club. The goals of the project are to 1) ensure adequate water for people

and environmental needs, 2) reduce future demand for water and foster efficient and sustainable use

of current water supplies, 3) educate the public and decision makers about the impact of wasteful

water use and the opportunities for water conservation, and 4) involve citizens in the decision

making process for water management.

A Primer On Brackish And Seawater Desalination

Abstract: This publication was produced as an activity of the Texas Living Waters Project. This project

is a collaborative effort of the National Wildlife Federation, Environmental Defense, and the Lone

Star Chapter of the Sierra Club. The goals of the project are to 1) ensure adequate water for people

and environmental needs, 2) reduce future demand for water and foster efficient and sustainable use

of current water supplies, 3) educate the public and decision makers about the impact of wasteful

water use and the opportunities for water conservation, and 4) involve citizens in the decision

making process for water management.

Tailoring Advanced Desalination Technologies for 21st Century Agriculture

Abstract: Substantial parts of the U.S., particularly drier landlocked regions, are facing acute water shortages and water quality issues that decrease agricultural productivity. Reduced crop yields cause billions of dollars in losses annually, affecting the livelihoods of thousands. A combination of population growth, inefficient agricultural practices, and resource demanding consumption trends is only expected to increase pressure on our water supplies. This research proposal seeks to address water and food security issues by cost-effectively and energy-efficiently enhancing water quality and water supply in greenhouses; a $22.93 billion dollar industry in 2017 that is rapidly growing at an annual rate of 8.92%. Greenhouses widely practice desalination of salty irrigation water to improve their operations. However, currently used desalination methods do not tailor greenhouse waters based on crop requirements. This work investigates a fully integrated desalination solution that treats and tailors brackish source waters ingreenhouses to save fertilizer and water. Specifically, this project experimentally studies multi-ion transport in and assesses the economic viable of monovalent selective electrodialysis (MSED). MSED allows for the selective removal of monovalent ions damaging to crops and the retention of divalent ions beneficial for crops, unlike the widely used reverse osmosis (RO), which removes all ions from greenhouse source water. First, we evaluate the techno-economic feasibility of MSED compared to other brackish desalination technologies for agricultural applications, based on primary market research we conduct with over 70 greenhouses.

These include conventional technologies, such as reverse osmosis (RO) and electrodialysis (ED), and advanced technologies, such as closed circuit reverse osmosis (CCRO). The analysis determines the levelized costs of water, the capital costs and energy requirements of these technologies, and how these vary with feed salinity, system capacity and recovery ratio. Then, we build a bench-scale setup to experientially characterize MSED membrane properties, including monovalent selectivity, ion transport, limiting current and resistance, for multiple brackish feedwaters and for two sets of MSED membranes: the widely used Neosepta ACS/CMS membranes and the new Fujifilm Type 16 membranes. Both MSED membranes show notable monovalent selectivity for all tested compositions, reflecting the potential of the technology for selective desalination in greenhouses. The measurements are compared to a model for MSED in multi-ion solutions. The model predicts multi-ion transport for the Neosepta and Fujifilm MSED systems within 6% and 8%, respectively.

Tailoring Advanced Desalination Technologies for 21st Century Agriculture

Abstract: Substantial parts of the U.S., particularly drier landlocked regions, are facing acute water shortages and water quality issues that decrease agricultural productivity. Reduced crop yields cause billions of dollars in losses annually, affecting the livelihoods of thousands. A combination of population growth, inefficient agricultural practices, and resource demanding consumption trends is only expected to increase pressure on our water supplies. This research proposal seeks to address water and food security issues by cost-effectively and energy-efficiently enhancing water quality and water supply in greenhouses; a $22.93 billion dollar industry in 2017 that is rapidly growing at an annual rate of 8.92%. Greenhouses widely practice desalination of salty irrigation water to improve their operations. However, currently used desalination methods do not tailor greenhouse waters based on crop requirements. This work investigates a fully integrated desalination solution that treats and tailors brackish source waters ingreenhouses to save fertilizer and water. Specifically, this project experimentally studies multi-ion transport in and assesses the economic viable of monovalent selective electrodialysis (MSED). MSED allows for the selective removal of monovalent ions damaging to crops and the retention of divalent ions beneficial for crops, unlike the widely used reverse osmosis (RO), which removes all ions from greenhouse source water. First, we evaluate the techno-economic feasibility of MSED compared to other brackish desalination technologies for agricultural applications, based on primary market research we conduct with over 70 greenhouses.

These include conventional technologies, such as reverse osmosis (RO) and electrodialysis (ED), and advanced technologies, such as closed circuit reverse osmosis (CCRO). The analysis determines the levelized costs of water, the capital costs and energy requirements of these technologies, and how these vary with feed salinity, system capacity and recovery ratio. Then, we build a bench-scale setup to experientially characterize MSED membrane properties, including monovalent selectivity, ion transport, limiting current and resistance, for multiple brackish feedwaters and for two sets of MSED membranes: the widely used Neosepta ACS/CMS membranes and the new Fujifilm Type 16 membranes. Both MSED membranes show notable monovalent selectivity for all tested compositions, reflecting the potential of the technology for selective desalination in greenhouses. The measurements are compared to a model for MSED in multi-ion solutions. The model predicts multi-ion transport for the Neosepta and Fujifilm MSED systems within 6% and 8%, respectively.

Desalination & Water Purification Technologies

Introduction:

The world’s water consumption rate is doubling every 20 years, outpacing by two times the rate of population growth. The availability of good quality water is on the decline and water demand is on the rise. Worldwide availability of fresh water for industrial needs and human consumption is limited.

Various industrial and developmental activities in recent times have resulted in increasing the pollution level and deteriorating the water quality. Water shortages and unreliable water quality are considered major obstacles to achieve sustainable development and improvement in the quality of life. The water

demand in the country is increasing fast due to progressive increase in the demand of water for irrigation, rapid industrialization, and population growth and improving life standards. The existing water resources are diminishing (i) due to unequal distribution of rain water and occasional drought, (ii) excessive exploitation of ground water sources and its insufficient recharge, (iii) deterioration of water quality due to the discharge of domestic and industrial effluents without adequate treatment. This is resulting into water stress/ scarcity. Country is currently passing through social and economic transition.

The proportion of the population which is urban has doubled over the last thirty years (and is now about 30%), agriculture now accounts for about 25% of GDP and the economy has been growing at around 7-9% a year. Country has a highly seasonal pattern of rainfall, with 50% of precipitation falling

in just 15 days and over 90% of river flows in just four months

Desalination & Water Purification Technologies

Introduction:

The world’s water consumption rate is doubling every 20 years, outpacing by two times the rate of population growth. The availability of good quality water is on the decline and water demand is on the rise. Worldwide availability of fresh water for industrial needs and human consumption is limited.

Various industrial and developmental activities in recent times have resulted in increasing the pollution level and deteriorating the water quality. Water shortages and unreliable water quality are considered major obstacles to achieve sustainable development and improvement in the quality of life. The water

demand in the country is increasing fast due to progressive increase in the demand of water for irrigation, rapid industrialization, and population growth and improving life standards. The existing water resources are diminishing (i) due to unequal distribution of rain water and occasional drought, (ii) excessive exploitation of ground water sources and its insufficient recharge, (iii) deterioration of water quality due to the discharge of domestic and industrial effluents without adequate treatment. This is resulting into water stress/ scarcity. Country is currently passing through social and economic transition.

The proportion of the population which is urban has doubled over the last thirty years (and is now about 30%), agriculture now accounts for about 25% of GDP and the economy has been growing at around 7-9% a year. Country has a highly seasonal pattern of rainfall, with 50% of precipitation falling

in just 15 days and over 90% of river flows in just four months

Desalination and Membrane Technologies: Federal Research and Adoption Issues

In the United States, desalination and membrane technologies are used to augment municipal water supply, produce high-quality industrial water supplies, and reclaim contaminated supplies (including from oil and gas development). Approximately 2,000 desalination facilities larger than

0.3 million gallons per day (MGD) operate in the United States; this represents more than 2% of U.S. municipal and industrial freshwater use. At issue for Congress is what should be the federal role in supporting desalination and membrane technology research and facilities. Desalination issues before the 114th Congress may include how to focus federal research, at what level to support desalination research and projects, and how to provide a regulatory context that protects the environment and public health without disadvantaging desalination’s adoption.

Desalination and Membrane Technologies: Federal Research and Adoption Issues

In the United States, desalination and membrane technologies are used to augment municipal water supply, produce high-quality industrial water supplies, and reclaim contaminated supplies (including from oil and gas development). Approximately 2,000 desalination facilities larger than

0.3 million gallons per day (MGD) operate in the United States; this represents more than 2% of U.S. municipal and industrial freshwater use. At issue for Congress is what should be the federal role in supporting desalination and membrane technology research and facilities. Desalination issues before the 114th Congress may include how to focus federal research, at what level to support desalination research and projects, and how to provide a regulatory context that protects the environment and public health without disadvantaging desalination’s adoption.

Cleaning Your RO

Eventually the day comes when your RO system will require cleaning. Cleaning is recommended when your RO shows evidence of fouling, just prior to a long term shutdown, or as a matter of scheduled routine maintenance. Fouling characteristics that signal you need to clean are a 10-15% decrease in normalized permeate flow, a 10-15% decrease in normalized permeate quality, or a 10-15% increase in normalized pressure drop as measured between the feed and concentrate headers

Cleaning Your RO

Eventually the day comes when your RO system will require cleaning. Cleaning is recommended when your RO shows evidence of fouling, just prior to a long term shutdown, or as a matter of scheduled routine maintenance. Fouling characteristics that signal you need to clean are a 10-15% decrease in normalized permeate flow, a 10-15% decrease in normalized permeate quality, or a 10-15% increase in normalized pressure drop as measured between the feed and concentrate headers

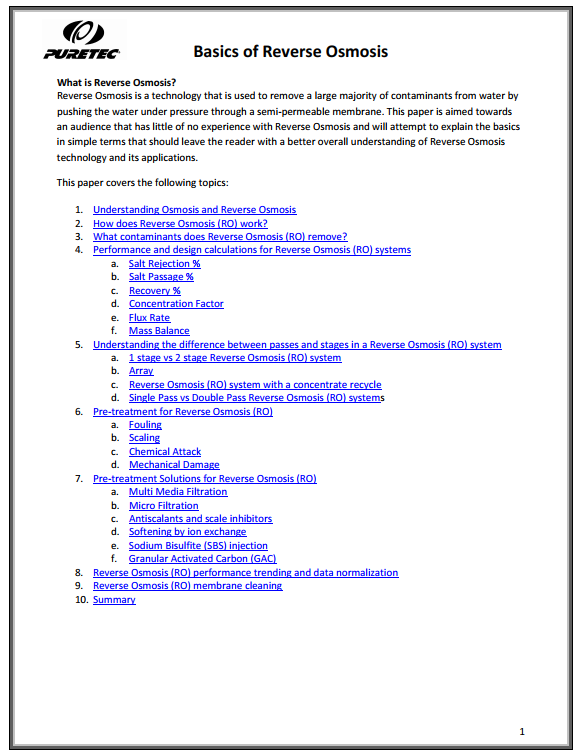

Basics of Reverse Osmosis

What is Reverse Osmosis?

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by

pushing the water under pressure through a semi permeable membrane. This paper is aimed towards an audience that has little of no experience with Reverse Osmosis and will attempt to explain the basics

in simple terms that should leave the reader with a better overall understanding of Reverse Osmosis technology and its applications.

Basics of Reverse Osmosis

What is Reverse Osmosis?

Reverse Osmosis is a technology that is used to remove a large majority of contaminants from water by

pushing the water under pressure through a semi permeable membrane. This paper is aimed towards an audience that has little of no experience with Reverse Osmosis and will attempt to explain the basics

in simple terms that should leave the reader with a better overall understanding of Reverse Osmosis technology and its applications.

Assessment Of Best Available Technologies For Desalination In Rural/Local Areas

Introduction: The Sustainable Water Integrated Management (SWIM) is a European Union(EU)-funded Regional Technical

Assistance Program [1] that “aims at supporting water governance and mainstreaming by promoting sustainable

and equitable water resources management to become a prominent feature of national development policies and

strategies (agriculture, industry, tourism, etc).” [2]

Countries in the south of the Mediterranean are facing increasing water scarcity. This scarcity is driving the need

for augmenting conventional water supply with alternative water sources. Rural and remote areas are particularly

disadvantaged because such areas are often located far away from municipal water supply systems and

conventional water sources, and are often not connected to the electric power grid. There is good potential for

addressing the water scarcity problem in rural and remote areas through sustainable saline water desalination

technologies. Seawater and brackish water desalination are well-established industries comprising a wide variety

of available technologies with decades of accumulated experience. There are many advancements and evolution in

desalination technologies. The numerous technologies and processes available have different characteristics,

advantages and disadvantages that make each suitable for particular market segments or specific niches.

Moreover, much of the cumulative technology experience is related to large urban supply plants that are either

connected to the grid, or are themselves part of large power and desalination cogeneration plants. Rural and

remote areas have special requirements that influence the appropriate selection of technologies. These include

technical requirements related to small-scale application using renewable energy sources, ease of operation and

maintenance, and simple design; requirements dictated by geographical location; as well as socio-economic and

socio-cultural requirements related to the communities that are intended to operate and benefit from the

technology. Successful implementation and long term sustainability (operational and environmental sustainability)

of desalination projects for rural and remote locations requires that all the relevant requirements be identified and

addressed from the earliest stages of the project.

Assessment Of Best Available Technologies For Desalination In Rural/Local Areas

Introduction: The Sustainable Water Integrated Management (SWIM) is a European Union(EU)-funded Regional Technical

Assistance Program [1] that “aims at supporting water governance and mainstreaming by promoting sustainable

and equitable water resources management to become a prominent feature of national development policies and

strategies (agriculture, industry, tourism, etc).” [2]

Countries in the south of the Mediterranean are facing increasing water scarcity. This scarcity is driving the need

for augmenting conventional water supply with alternative water sources. Rural and remote areas are particularly

disadvantaged because such areas are often located far away from municipal water supply systems and

conventional water sources, and are often not connected to the electric power grid. There is good potential for

addressing the water scarcity problem in rural and remote areas through sustainable saline water desalination

technologies. Seawater and brackish water desalination are well-established industries comprising a wide variety

of available technologies with decades of accumulated experience. There are many advancements and evolution in

desalination technologies. The numerous technologies and processes available have different characteristics,

advantages and disadvantages that make each suitable for particular market segments or specific niches.

Moreover, much of the cumulative technology experience is related to large urban supply plants that are either

connected to the grid, or are themselves part of large power and desalination cogeneration plants. Rural and

remote areas have special requirements that influence the appropriate selection of technologies. These include

technical requirements related to small-scale application using renewable energy sources, ease of operation and

maintenance, and simple design; requirements dictated by geographical location; as well as socio-economic and

socio-cultural requirements related to the communities that are intended to operate and benefit from the

technology. Successful implementation and long term sustainability (operational and environmental sustainability)

of desalination projects for rural and remote locations requires that all the relevant requirements be identified and

addressed from the earliest stages of the project.

Advanced Reverse Osmosis System Design

Overview of Advanced RO Design

• RO system design guideline variables

• Drivers for RO system configuration selection

• Principles and benefits of RO array flux balancing

• Array selection criteria to achieve permeate quality target

• Energy recovery

Advanced Reverse Osmosis System Design

Overview of Advanced RO Design

• RO system design guideline variables

• Drivers for RO system configuration selection

• Principles and benefits of RO array flux balancing

• Array selection criteria to achieve permeate quality target

• Energy recovery

Desalination: A National Perspective

NOTICE:

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The members of the panel responsible for the report were chosen for their special competences and with regard for appropriate balance.

Support for this study was provided by the U.S. Bureau of Reclamation under Grant No. 06CS811198. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the organizations or agencies that provided

support for the project.

Desalination: A National Perspective

NOTICE:

The project that is the subject of this report was approved by the Governing Board of the National Research Council, whose members are drawn from the councils of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine. The members of the panel responsible for the report were chosen for their special competences and with regard for appropriate balance.

Support for this study was provided by the U.S. Bureau of Reclamation under Grant No. 06CS811198. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the organizations or agencies that provided

support for the project.

Reviews

There are no reviews yet.