Tracer and Timescale Methods for Passive and Reactive Transport in Fluid Flows

Timescales and tracer-based methods have been recognized to be powerful approaches to gain quantitative insight into the underlying physical and biochemical processes in oceanography, limnology, and marine science, and have widely been used to interpret field observations and numerical model results. The concept of timescales has been instrumental to understanding the complex hydrodynamics and transport processes of reactive biochemical substances in surface waters since Bolin and Rodhe introduced timescales of age, transit time, and turnover time in 1973. In 1976, Zimmerman applied the timescale concept to the DutchWadden Sea and introduced ‘residence time’ to deal with moving individual particles for a spatially varying situation. Takeoka further studied residence time in 1984 under the same framework as Bolin and Rodhe.

Tracer and Timescale Methods for Passive and Reactive Transport in Fluid Flows

Timescales and tracer-based methods have been recognized to be powerful approaches to gain quantitative insight into the underlying physical and biochemical processes in oceanography, limnology, and marine science, and have widely been used to interpret field observations and numerical model results. The concept of timescales has been instrumental to understanding the complex hydrodynamics and transport processes of reactive biochemical substances in surface waters since Bolin and Rodhe introduced timescales of age, transit time, and turnover time in 1973. In 1976, Zimmerman applied the timescale concept to the DutchWadden Sea and introduced ‘residence time’ to deal with moving individual particles for a spatially varying situation. Takeoka further studied residence time in 1984 under the same framework as Bolin and Rodhe.

The Effect of Hydrology on Soil Erosion

Abstract: In this Special Issue, we have tried to include manuscripts about soil erosion and degradation processes and the accelerated rates due to hydrological processes and climate change. We considered that the main goal was successfully reached. The new research focused on measurements, modelling, and experiments under field or laboratory conditions developed at different scales (pedon, hillslope, and catchment) were submitted and published. This Special Issue received investigations from different parts of the world such as Ethiopia, Morocco, China, Iran, Italy, Portugal, Greece and Spain, among others. We are happy to see that all papers presented findings characterized as unconventional, provocative, innovative and methodologically new. We hope that the readers of the journal Water can enjoy and learn about hydrology and soil erosion using the published material, and share the results with the scientific community, policymakers and stakeholders new research to continue this amazing adventure, featuring plenty of issues and challenges.

The Effect of Hydrology on Soil Erosion

Abstract: In this Special Issue, we have tried to include manuscripts about soil erosion and degradation processes and the accelerated rates due to hydrological processes and climate change. We considered that the main goal was successfully reached. The new research focused on measurements, modelling, and experiments under field or laboratory conditions developed at different scales (pedon, hillslope, and catchment) were submitted and published. This Special Issue received investigations from different parts of the world such as Ethiopia, Morocco, China, Iran, Italy, Portugal, Greece and Spain, among others. We are happy to see that all papers presented findings characterized as unconventional, provocative, innovative and methodologically new. We hope that the readers of the journal Water can enjoy and learn about hydrology and soil erosion using the published material, and share the results with the scientific community, policymakers and stakeholders new research to continue this amazing adventure, featuring plenty of issues and challenges.

Toward Responsible and Informed Ocean-Based Carbon Dioxide Removal

Executive Summary

Ocean carbon dioxide removal approaches have been gaining prominence in international and national climate policy. Yet many of these

approaches remain untested with significant scientific gaps and risks to the marine environment and coastal communities. Striking the right balance between the urgency of emission reductions and using appropriate ocean carbon dioxide removal approaches without causing further harm to ocean systems, ecosystems, and coastal communities will require an iterative and adaptive approach that

prioritizes responsible and informed development.

Toward Responsible and Informed Ocean-Based Carbon Dioxide Removal

Executive Summary

Ocean carbon dioxide removal approaches have been gaining prominence in international and national climate policy. Yet many of these

approaches remain untested with significant scientific gaps and risks to the marine environment and coastal communities. Striking the right balance between the urgency of emission reductions and using appropriate ocean carbon dioxide removal approaches without causing further harm to ocean systems, ecosystems, and coastal communities will require an iterative and adaptive approach that

prioritizes responsible and informed development.

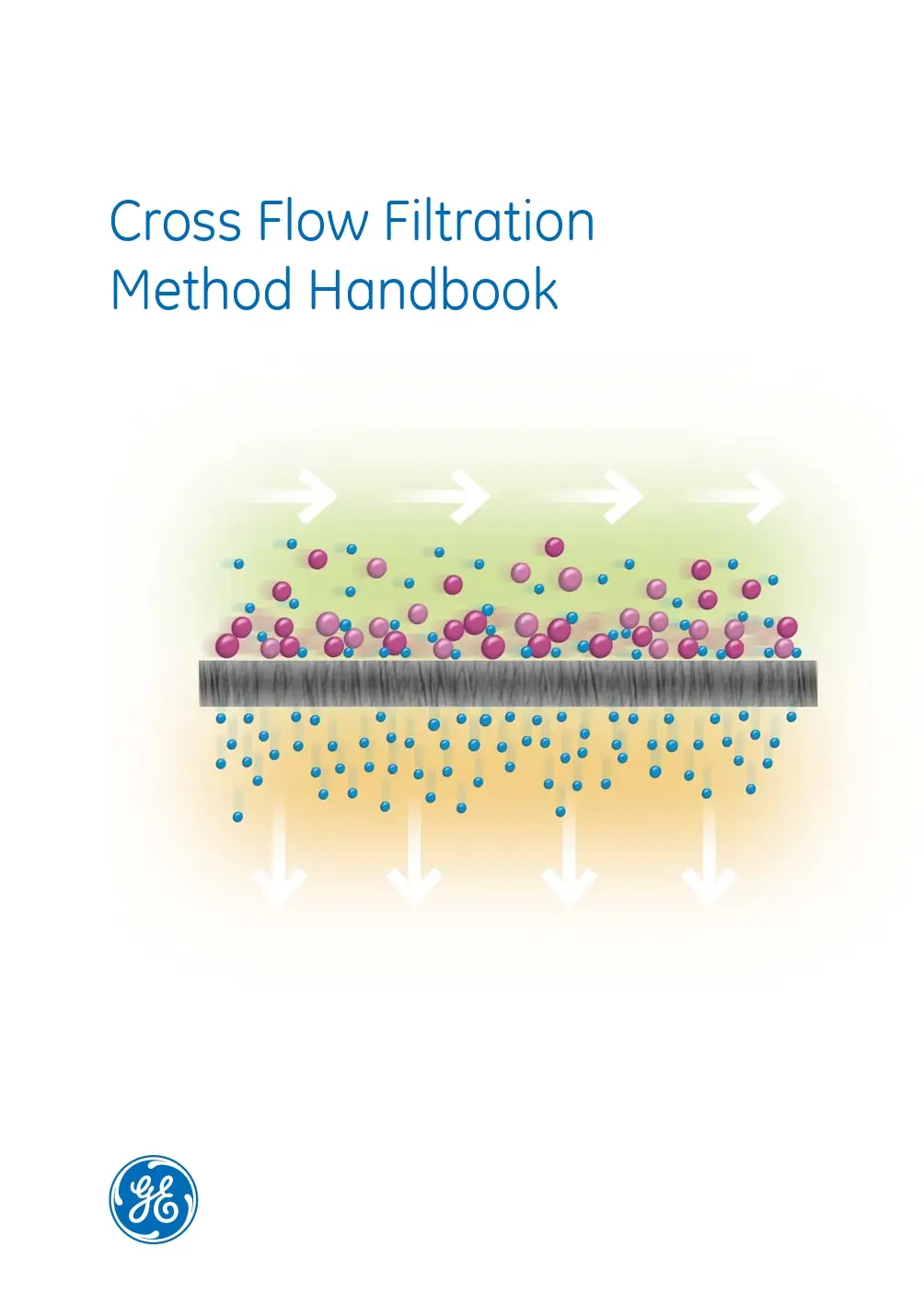

Cross Flow Filtration Method Handbook

The Cross Flow Filtration Method Handbook gives a general introduction to the principles and applications of cross flow filtration using systems and filters from GE. Detailed instructions for preparing, using, cleaning and storing particular filters are provided with each filter.

Cross Flow Filtration Method Handbook

The Cross Flow Filtration Method Handbook gives a general introduction to the principles and applications of cross flow filtration using systems and filters from GE. Detailed instructions for preparing, using, cleaning and storing particular filters are provided with each filter.